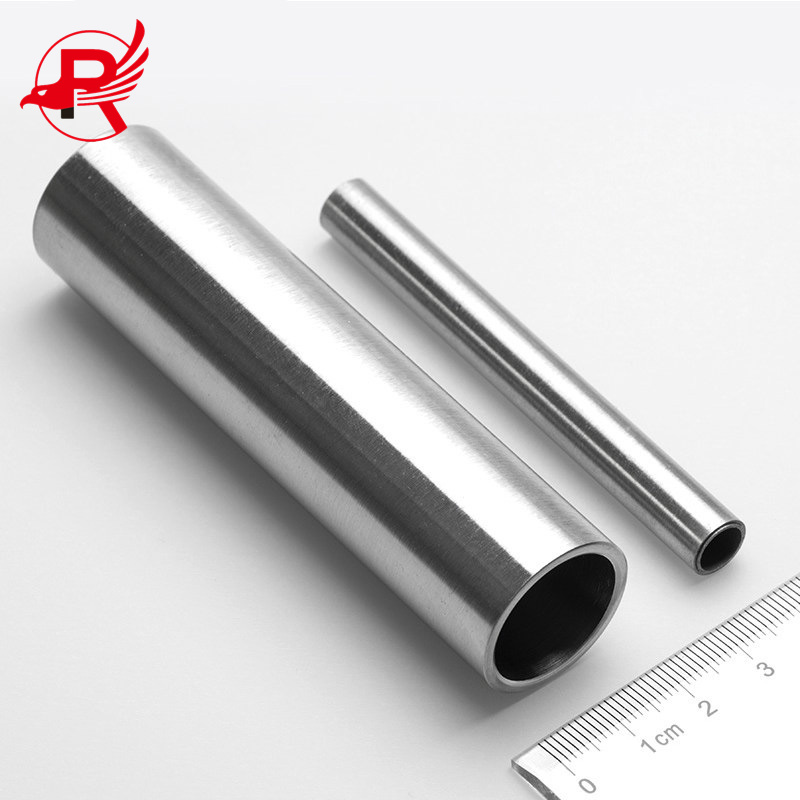

1mm 2mm Boleng bo Holimo 410 420 430 440 Tšepe e sa Khaotseng Pipe SS Tube

| tem | 410 420 430 440Phaephe ea Tšepe e sa Hloekeng |

| E tloaelehileng | JIS, AiSi, ASTM, GB, DIN, EN |

| Sebaka sa Tšimoloho | Chaena |

| Lebitso la Letšoao | BORASO |

| Mofuta | Ha e na seamless / e tjheseletsa |

| Kereiti ea Tšepe | Letoto la 200/300/400, 904L S32205 (2205),S32750(2507) |

| Kopo | Indasteri ea lik'hemik'hale, lisebelisoa tsa mechini |

| Tšebeletso ea Ts'ebetso | Ho kobeha, ho tjheseletsa, ho qhibilihisa, ho phunya, ho seha, ho bopa |

| Mokhoa | E phutholohile e chesang/e batang e phutholohile |

| Melao ea tefo | T/T (30% depositi) |

| Nako ea Theko | CIF CFR FOB EX-WORK |

Phaephe ea tšepe e sa hloekang ke mofuta oa tšepe e chitja e se nang letho, e sebelisoang haholo-holo liphaepheng tsa lipalangoang tsa indasteri tse kang peterole, indasteri ea lik'hemik'hale, kalafo ea bongaka, lijo, indasteri e bobebe, lisebelisoa tsa mechini, jj., hammoho le likarolo tsa sebopeho sa mechini. Ho feta moo, ha matla a kobehileng le a torsional a tšoana, boima bo bobebe, kahoo e boetse e sebelisoa haholo tlhahisong ea likarolo tsa mechini le meaho ea boenjiniere. E boetse e sebelisoa hangata e le thepa ea ka tlung le lisebelisoa tsa kichine, jj.

Hlokomela:

1. Ho etsa sampole mahala, 100% tiisetso ea boleng kamora thekiso, Tšehetsa mokhoa ofe kapa ofe oa tefo;

2. Litlhaloso tse ling kaofela tsa liphaephe tsa tšepe ea khabone e chitja lia fumaneha ho latela tlhoko ea hau (OEM & ODM)! Theko ea fektheri eo u tla e fumana ho ROYAL GROUP.

Lisebelisoa tsa lik'hemik'hale tsa Pipe ea Tšepe e sa Khaotseng

| Sebopeho sa Lik'hemik'hale % | ||||||||

| Sehlopha | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0 .15 | ≤0 .75 | 5. 5-7. 5 | ≤0.06 | ≤ 0.03 | 3.5 -5.5 | 16 .0 -18.0 | - |

| 202 | ≤0 .15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - |

| 301 | ≤0 .15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - |

| 302 | ≤0 .15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - |

| 304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0 .03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 - 15.0 | 16 .0 -1 8.0 | 2.0 -3.0 |

| 321 | ≤ 0 .08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 - 13.0 | 17.0 -1 9.0 | - |

| 630 | ≤ 0 .07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - |

| 631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - |

| 904L | ≤ 2.0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0·28.0 | 19.0-23.0 | 4.0-5.0 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19 -0. 22 | 0. 24 -0 . 26 | - |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - |

| 430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | |

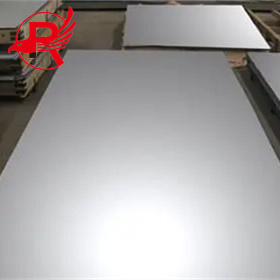

Ka mekhoa e fapaneng ea ts'ebetso ea ho phutholla ka mokhoa o batang le ho lokisa bokaholimo ka mor'a ho phutholla, bokaholimo ba tšepe e sa hloekangbares e ka ba le mefuta e fapaneng.

Ho na le mefuta e mengata ea kalafo ea bokaholimo bakeng sa phaephe ea tšepe e sa ruseng, e 'ngoe le e 'ngoe e na le litšobotsi le melemo ea eona e ikhethang.

E 'ngoe ea mefuta e tloaelehileng ea kalafo ea bokaholimo bakeng sa phaephe ea tšepe e sa ruseng ke kalafo ea 2B. Kalafo ena ea bokaholimo e finyelloa ka ho phutholla lakane ea tšepe e sa ruseng ka serame ebe e e khomaretsa. Bokaholimo bo hlahang bo na le qetello e boreleli, e sa hlakang, e loketseng lits'ebetso moo botle e seng taba ea bohlokoa.

Qetello e 'ngoe e tsebahalang bakeng sa phaephe ea tšepe e sa ruseng ke qetello e foreshelitsoeng. Qetello ena e finyelloa ka ho sebelisa borashe ba terata ho etsa mela e otlolohileng kapa e otlolohileng holim'a phaephe ea tšepe e sa ruseng. Qetello e foreshelitsoeng hangata e sebelisoa lits'ebetsong moo botle e leng ntlha ea bohlokoa, joalo ka lits'ebetso tsa meralo kapa tsa mekhabiso. Ntle le kalafo ea bokaholimo ba 2B le boreshelitsoeng, liphaephe tsa tšepe e sa ruseng le tsona li na le mefuta e meng ea kalafo ea bokaholimo, joalo ka kalafo ea bokaholimo ba BA le kalafo ea bokaholimo ba seipone.

Qetello ea BA e fihlelleha ka ho hokela tšepe e sa hloekang ka khanya e khanyang, e leng se fellang ka qetello e bonahatsang haholo holim'a eona. Phello ea seipone e fihlelleha ka ho bentša bokaholimo ba tšepe e sa hloekang hore bo be benyang haholo, e leng se fellang ka ponahalo e kang ea seipone.

Khetho ea qetello ea bokaholimo bakeng sa liphaephe tsa tšepe e sa ruseng e itšetlehile ka lintlha tse 'maloa tse kang ts'ebeliso, tikoloho le botle bo lakatsehang. Mohlala, qetello ea 2B e ka ba e loketseng lits'ebetso tsa indasteri moo botle e seng ntlha ea bohlokoa, ha qetello e foreshe kapa e nang le seipone e ka ba e loketseng lits'ebetso tsa meralo kapa tsa mekhabiso. Qetellong, qetello ea bokaholimo ba phaephe ea tšepe e sa ruseng ke ntlha ea bohlokoa e amang ts'ebetso ea eona le ho tšoarella ha eona.

Mekhoa e fapaneng ea phekolo ea bokaholimo e fana ka thepa le melemo e fapaneng ho latela ts'ebeliso le botle bo lakatsehang. Liphaephe tsa tšepe e sa ruseng li ntse li le thepa e tsebahalang liindastering tse fapaneng, 'me qetello ea bokaholimo ba eona e bapala karolo ea bohlokoa katlehong ea eona.

Ts'ebetso e ka sehloohong ea tlhahiso: tšepe e chitja → tlhahlobo-bocha → ho petsoha → ho koala → ho betla → ho bohareng → ho futhumatsa → ho phunyeletsa → ho pickling → hlooho e bataletseng → tlhahlobo le ho sila → ho phutholla ka serame (ho taka ho batang) → ho tlosa mafura → kalafo ea mocheso → ho otlolla → ho seha phaephe (e tsitsitseng bolelele) ) → ho pickling/passivation → tlhahlobo ea sehlahisoa e felileng (motlakase oa eddy, ultrasonic, khatello ea metsi) → ho paka le ho boloka.

Mohato oa pele tlhahisong ealiphaephe tsa tšepe e sa hloekangke khetho ea thepa e tala. Tšepe e sa ruseng e entsoe ka tšepe, chromium, le litšepe tse ling tse fapaneng tse kang nickel, molybdenum, kapa titanium. Ho bohlokoa ho khetha thepa e tala ea boleng bo holimo ho netefatsa boleng le litšobotsi tse ntle ka ho fetisisa tsa sehlahisoa se felileng.

Hang ha thepa e tala e se e kgethilwe, mohato o latelang tshebetsong ya tlhahiso ke ho qhibilihisa tshepe ka ontong. Tshepe e qhibilihisitsweng e tshelwa ka hara foromo ho etsa billet e tiileng.

Ebe billet e romelwa leloaleng le tjhesang moo e bopjwang ka sebopeho se lakatsehang. Tshepe e tjhesang e tjhesang e bewa tlasa kalafo e eketsehileng ya mocheso, jwalo ka ho e annealing kapa ho e tima, ho ntlafatsa thepa ya yona. Ho annealing ho kenyeletsa ho futhumatsa tshepe mochesong o phahameng ebe ho e phodisa butle ho e etsa hore e be bonolo le e dule hanyane. Ho e tima ho kenyeletsa tshepe e pholileng ka potlako ho e futhumatsa le ho e etsa hore e be matla.

Mohato o latelang tlhahisong ke ho sebetsa ka mechine.Liphaephe tsa tšepe e sa hloekange etsoa ka mechini ho fihlela sebopeho sa eona sa ho qetela, boholo le bolelele ho sebelisoa lisebelisoa tse fapaneng ho kenyeletsoa le li-lathe, mechini ea ho sila le li-drill.

Ts'ebetso ea ho sebetsa ka mochini e ka boela ea kenyelletsa ho tlosa mefokolo efe kapa efe ea bokaholimo joalo ka ho teteana kapa li-burrs. Kamora ts'ebetso ea ho sebetsa ka mochini, liphaephe tsa tšepe e sa hloekang lia hloekisoa ho tlosa tšilafalo efe kapa efe pele li romeloa tlhahlobong. Ena ke mohato oa bohlokoa ho netefatsa hore sehlahisoa se felileng se fihlela litlhoko tse hlokahalang le maemo a boleng.

Ts'ebetso ea teko e kenyelletsa tlhahlobo ea khatello, tlhahlobo ea likaroloana tsa makenete, tlhahlobo ea ultrasound le liteko tse ling. Qetellong, phaephe ea tšepe e sa ruseng e felile 'me e loketse ho romelloa kapa ho kenngoa.

Liphaephe li ka fuoa mekhoa e fapaneng ea phekolo ea bokaholimo joalo ka ho li polisha, ho li sila kapa ho li polisha ka motlakase ho ntlafatsa ponahalo ea tsona le ho hanyetsa mafome.

Qetellong, ts'ebetso ea tlhahiso ea phaephe ea tšepe e sa hloekang e rarahane 'me e hloka boiphihlelo le tlhokomelo ho lintlha tse qaqileng. Leha ho le joalo, melemo ea phaephe ea tšepe e sa hloekang e etsa hore e be thepa e tsebahalang liindastering tse fapaneng. Ts'ebetso ea ho khetha thepa e tala ea boleng bo holimo, ho qhibilihisa, ho lahla, ho pitikisa, ho phekola mocheso, ho sebetsa ka machining, ho hlahloba le ho qeta e fella ka sehlahisoa se tšoarellang, se sa senyeheng se ka mamellang maemo a thata le ho fana ka lilemo tsa tšebeletso e tšepahalang.

Sephutheloana hangata ha se na letho, se tlama terata ea tšepe, se matla haholo.

Haeba o na le litlhoko tse khethehileng, o ka sebelisa sephutheloana se thibelang mafome, 'me se be setle haholoanyane.

Lipalangoang:Ka potlako (Tlhahiso ea Mehlala), Ka Sefofane, Terene, Naheng, Thomello ea Leoatleng (FCL kapa LCL kapa Bongata)

Moreki oa Rona

P: Na ke moetsi oa UA?

K: E, re moetsi. Re na le fektheri ea rona e Tianjin City, Chaena.

P: Na nka fumana odara ea teko ea lithane tse 'maloa feela?

K: Ehlile. Re ka o romella thepa ka tšebeletso ea LCL. (Mojaro o fokolang oa lijana)

P: Haeba sampole e lokolohile?

K: Sampole ha e fumanehe, empa moreki o lefella thepa.

P: Na o fana ka khauta mme o etsa tiisetso ya kgwebo?

K: Re fana ka khauta ka lilemo tse supileng 'me re amohela tiisetso ea khoebo.