Pipe ea Mohala oa Tšepe ea Khabone ea API 5L B/X42 /X52 /X60 /X65 Psl2

| Mekhahlelo | API 5L Kereiti ea B, X42, X52, X56, X60, X65, X70, X80 |

| Boemo ba Tlhaloso | PSL1, PSL2 |

| Bophara ba Bophara ba Kantle | 1/2” ho isa ho 2”, 3”, 4”, 6”, 8”, 10”, 12”, 16 inches, 18 inches, 20 inches, 24 inches ho fihlela ho 40 inches. |

| Kemiso ea Botenya | SCH 10. SCH 20, SCH 40, SCH STD, SCH 80, SCH XS, ho isa ho SCH 160 |

| Mefuta ea Tlhahiso | Ha e na seamless (E phuthoa ka ho Chesa le e Batang), ERW e Welded (e phuthetsoe ka ho hanyetsa motlakase), SAW (E qoelitsoeng ka Arc Welded) ho LSAW, DSAW, SSAW, HSAW |

| Mofuta oa Lipheletso | Lipheletso tse betliloeng, Lipheletso tse se nang letho |

| Bolelele ba Nako | SRL (Bolelele bo le Bong bo sa Ratehang), DRL (Bolelele bo habeli bo sa Ratehang), 20 FT (limithara tse 6), 40FT (limithara tse 12) kapa, e etselitsoeng motho ka mong |

| Li-cap tsa Tšireletso | polasetiki kapa tšepe |

| Phekolo ea Bokaholimo | Pente ea tlhaho, e nang le varnish, e ntšo, FBE, 3PE (3LPE), 3PP, CWC (E koahetsoeng ka boima ba konkreite) CRA e koahetsoeng kapa e nang le mela |

Phaephe ea API 5L e bolela phaephe ea tšepe ea khabone e sebelisoang lits'ebetsong tsa phetisetso ea oli le khase. E boetse e sebelisetsoa ho tsamaisa maro a mang a kang mouoane, metsi le seretse.

Tlhaloso ea API 5L e akaretsa mefuta ea tlhahiso e bōpehileng ka welded le e se nang seamless.

Mefuta e Welded: ERW, SAW, DSAW, LSAW, SSAW, HSAW Pipe

Mefuta e tloaelehileng ea phaephe e welded ea API 5L ke e latelang:

ERW: Ho tjheseletsa ho hanyetsa motlakase ho sebediswa bakeng sa phaephe e nang le bophara bo ka tlase ho lisenthimithara tse 24.

DSAW/ SAW: Ho tjheseletsa arc e kenelletseng ka mahlakore a mabedi/ho tjheseletsa arc e kenelletseng ka metsing ke mokhoa o mong wa ho tjheseletsa o ka sebediswang sebakeng sa ERW bakeng sa phaephe e kgolo.

LSAW: Ho tjheseletsa Arc e Kenelletseng ka Longitudinal ho sebediswa bakeng sa phaephe e bophara ba lisenthimithara tse 48. E tsejwa e le mokhoa wa ho theha JCOE.

SSAW/HSAW: Ho tjheseletsa arc e kenelletseng ka hare ho spiral/ho tjheseletsa arc e kenelletseng ka hare ho spiral e fihlang ho di-inchi tse 100 bophara ba phaephe.

Mefuta ea Liphaephe tse se nang Mohele: Pipe e se nang Mohele e Chesang le Pipe e se nang Mohele e sa Chesang

Phaephe e se nang mohele hangata e sebelisoa bakeng sa liphaephe tse nyane tse bophara (hangata tse ka tlase ho lisenthimithara tse 24).

(Phaephe ea tšepe e se nang mohele e sebelisoa haholo ho feta phaephe e tjheselitsoeng bakeng sa bophara ba phaephe bo ka tlase ho 150 mm (li-inchi tse 6).

Re boetse re fana ka phaephe e se nang moedi e kgolo e bophara ba lisenthimithara tse 10. Re sebelisa mokhoa oa tlhahiso o phuthoang ka ho chesa, re ka hlahisa phaephe e se nang moedi e bophara ba lisenthimithara tse 508. Haeba u hloka phaephe e se nang moedi e boholo ba lisenthimithara tse 10, re ka e hlahisa re sebelisa mokhoa o atolositsoeng ka ho chesa o bophara ba lisenthimithara tse 1016.

API 5L e totobatsa limaraka tse latelang: Kereiti ea B, X42, X46, X52, X56, X60, X65, X70, le X80.

Ho na le mefuta e mengata e fapaneng ea tšepe bakeng sa phaephe ea tšepe ea API 5L joalo ka Sehlopha sa B, X42, X46, X52, X56, X60, X65, X70, le X80. Ka keketseho ea sehlopha sa tšepe, taolo e lekanang le khabone e thatafala haholoanyane, matla a mechini a phahame.

Hape, sebopeho sa lik'hemik'hale sa liphaephe tse se nang sekoli le tse phuthetsoeng tsa API 5L bakeng sa sehlopha se itseng ha se tšoane, phaephe e phuthetsoeng e na le litlhoko tse phahameng le khabone le sebabole tse fokolang.

Sebopeho sa Lik'hemik'hale bakeng sa phaephe ea PSL 1 e nang le t ≤ 0.984” | |||||||

| Kereiti ea Tšepe | Karolo e kholo, % e ipapisitse le mocheso le tlhahlobo ea sehlahisoa a, g | ||||||

| C | Mn | P | S | V | Nb | Ti | |

| boholo ba b | boholo ba b | boholo | boholo | boholo | boholo | boholo | |

| Pipe e se nang seamless | |||||||

| A | 0.22 | 0.9 | 0.03 | 0.03 | – | – | – |

| B | 0.28 | 1.2 | 0.03 | 0.03 | c,d | c,d | d |

| X42 | 0.28 | 1.3 | 0.03 | 0.03 | d | d | d |

| X46 | 0.28 | 1.4 | 0.03 | 0.03 | d | d | d |

| X52 | 0.28 | 1.4 | 0.03 | 0.03 | d | d | d |

| X56 | 0.28 | 1.4 | 0.03 | 0.03 | d | d | d |

| X60 | 0.28 e | 1.40 e | 0.03 | 0.03 | f | f | f |

| X65 | 0.28 e | 1.40 e | 0.03 | 0.03 | f | f | f |

| X70 | 0.28 e | 1.40 e | 0.03 | 0.03 | f | f | f |

| Pipe e nang le Welded | |||||||

| A | 0.22 | 0.9 | 0.03 | 0.03 | – | – | – |

| B | 0.26 | 1.2 | 0.03 | 0.03 | c,d | c,d | d |

| X42 | 0.26 | 1.3 | 0.03 | 0.03 | d | d | d |

| X46 | 0.26 | 1.4 | 0.03 | 0.03 | d | d | d |

| X52 | 0.26 | 1.4 | 0.03 | 0.03 | d | d | d |

| X56 | 0.26 | 1.4 | 0.03 | 0.03 | d | d | d |

| X60 | 0.26 e | 1.40 e | 0.03 | 0.03 | f | f | f |

| X65 | 0.26 e | 1.45 e | 0.03 | 0.03 | f | f | f |

| X70 | 0.26e | 1.65 e | 0.03 | 0.03 | f | f | f |

| a. Cu ≤ = 0,50% Ni; ≤ 0,50%; Cr ≤ 0,50%; le Mo ≤ 0.15%, | |||||||

| b. Bakeng sa phokotso e 'ngoe le e 'ngoe ea 0.01% ka tlase ho khabone e boletsoeng ka holimo, keketseho ea 0.05% ka holimo ho khabone e boletsoeng ka holimo bakeng sa Mn ea lumelloa, ho fihlela ho 1.65% bakeng sa likhakanyo ≥ L245 kapa B, empa ≤ L360 kapa X52; ho fihlela ho 1.75% bakeng sa likhakanyo > L360 kapa X52, empa < L485 kapa X70; le ho fihlela ho 2.00% bakeng sa khabone. | |||||||

| c. Ntle le haeba ho dumellanwe ka tsela e nngwe. NB + V ≤ 0.06%, | |||||||

| d. Nb + V + TI ≤ 0.15%, | |||||||

| e. Ntle le haeba ho dumellanwe ka tsela e nngwe., | |||||||

| f. Ntle le haeba ho dumellanwe ka tsela e nngwe, NB + V = Ti ≤ 0.15%, | |||||||

| g. Ha ho dumellwe ho eketsa B ka boomo mme B e setseng ≤ 0.001% | |||||||

| Sebopeho sa Lik'hemik'hale bakeng sa phaephe ea PSL 2 e nang le t ≤ 0.984” | |||||||||||||||||||||

| Kereiti ea Tšepe | Karolo e kholo, % e ipapisitse le tlhahlobo ea mocheso le sehlahisoa | Tekanyo ea Khabone | |||||||||||||||||||

| C | Si | Mn | P | S | V | Nb | Ti | Tse ling | CE IIW | CE Pcm | |||||||||||

| boholo ba b | boholo | boholo ba b | boholo | boholo | boholo | boholo | boholo | boholo | boholo | ||||||||||||

| Pipe e se nang seamless le e nang le welded | |||||||||||||||||||||

| BR | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | c | c | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X42R | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | 0.06 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| BN | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | c | c | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X42N | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | 0.06 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X46N | 0.24 | 0.4 | 1.4 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | d,e,l | 0.43 | 0.25 | ||||||||||

| X52N | 0.24 | 0.45 | 1.4 | 0.025 | 0.015 | 0.1 | 0.05 | 0.04 | d,e,l | 0.43 | 0.25 | ||||||||||

| X56N | 0.24 | 0.45 | 1.4 | 0.025 | 0.015 | 0.10f | 0.05 | 0.04 | d,e,l | 0.43 | 0.25 | ||||||||||

| X60N | 0.24f | 0.45f | 1.40f | 0.025 | 0.015 | 0.10f | 0.05f | 0.04f | g,h,l | Joalokaha ho lumellanoe | |||||||||||

| BQ | 0.18 | 0.45 | 1.4 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X42Q | 0.18 | 0.45 | 1.4 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X46Q | 0.18 | 0.45 | 1.4 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X52Q | 0.18 | 0.45 | 1.5 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X56Q | 0.18 | 0.45f | 1.5 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X60Q | 0.18f | 0.45f | 1.70f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X65Q | 0.18f | 0.45f | 1.70f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X70Q | 0.18f | 0.45f | 1.80f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X80Q | 0.18f | 0.45f | 1.90f | 0.025 | 0.015 | g | g | g | ke,j | Joalokaha ho lumellanoe | |||||||||||

| X90Q | 0.16f | 0.45f | 1.9 | 0.02 | 0.01 | g | g | g | j,k | Joalokaha ho lumellanoe | |||||||||||

| X100Q | 0.16f | 0.45f | 1.9 | 0.02 | 0.01 | g | g | g | j,k | Joalokaha ho lumellanoe | |||||||||||

| Pipe e nang le Welded | |||||||||||||||||||||

| BM | 0.22 | 0.45 | 1.2 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X42M | 0.22 | 0.45 | 1.3 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X46M | 0.22 | 0.45 | 1.3 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X52M | 0.22 | 0.45 | 1.4 | 0.025 | 0.015 | d | d | d | e,l | 0.43 | 0.25 | ||||||||||

| X56M | 0.22 | 0.45f | 1.4 | 0.025 | 0.015 | d | d | d | e,l | 0.43 | 0.25 | ||||||||||

| X60M | 0.12f | 0.45f | 1.60f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X65M | 0.12f | 0.45f | 1.60f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X70M | 0.12f | 0.45f | 1.70f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X80M | 0.12f | 0.45f | 1.85f | 0.025 | 0.015 | g | g | g | ke,j | .043f | 0.25 | ||||||||||

| X90M | 0.1 | 0.55f | 2.10f | 0.02 | 0.01 | g | g | g | ke,j | – | 0.25 | ||||||||||

| X100M | 0.1 | 0.55f | 2.10f | 0.02 | 0.01 | g | g | g | ke,j | – | 0.25 | ||||||||||

| a. SMLS t>0.787”, Meeli ea CE e tla ba joalo ka ha ho lumellanoe. Meeli ea CEIIW e sebelisitsoeng fi C > 0.12% le meeli ea CEPcm ea sebetsa haeba C ≤ 0.12%, | |||||||||||||||||||||

| b. Bakeng sa phokotso e 'ngoe le e 'ngoe ea 0.01% ka tlase ho tekanyo e boletsoeng bakeng sa C, keketseho ea 0.05% ka holimo ho tekanyo e boletsoeng bakeng sa Mn ea lumelloa, ho fihlela ho tekanyo e phahameng ea 1.65% bakeng sa limaraka ≥ L245 kapa B, empa ≤ L360 kapa X52; ho fihlela ho tekanyo e phahameng ea 1.75% bakeng sa limaraka > L360 kapa X52, empa < L485 kapa X70; ho fihlela ho tekanyo e phahameng ea 2.00% bakeng sa limaraka ≥ L485 kapa X70, empa ≤ L555 kapa X80; le ho fihlela ho tekanyo e phahameng ea 2.20% bakeng sa limaraka > L555 kapa X80. | |||||||||||||||||||||

| c. Ntle le haeba ho dumellanwe ka tsela e nngwe Nb = V ≤ 0.06%, | |||||||||||||||||||||

| d. Nb = V = Ti ≤ 0.15%, | |||||||||||||||||||||

| e. Ntle le haeba ho lumellane ka tsela e 'ngoe, Cu ≤ 0.50%; Ni ≤ 0.30% Cr ≤ 0.30% le Mo ≤ 0.15%, | |||||||||||||||||||||

| f. Ntle le haeba ho dumellanwe ka tsela e nngwe, | |||||||||||||||||||||

| g. Ntle le haeba ho dumellanwe ka tsela e nngwe, Nb + V + Ti ≤ 0.15%, | |||||||||||||||||||||

| h. Ntle le haeba ho lumellane ka tsela e 'ngoe, Cu ≤ 0.50% Ni ≤ 0.50% Cr ≤ 0.50% le MO ≤ 0.50%, | |||||||||||||||||||||

| ke. Ntle le haeba ho lumellane ka tsela e 'ngoe, Cu ≤ 0.50% Ni ≤ 1.00% Cr ≤ 0.50% le MO ≤ 0.50%, | |||||||||||||||||||||

| j. B ≤ 0.004%, | |||||||||||||||||||||

| k. Ntle le haeba ho lumellane ka tsela e 'ngoe, Cu ≤ 0.50% Ni ≤ 1.00% Cr ≤ 0.55% le MO ≤ 0.80%, | |||||||||||||||||||||

| l. Bakeng sa dikereiti tsohle tsa PSL 2 tsa phaephe ntle le dikereiti tse nang le dintlha tse boletsweng tlase j, tse latelang di a sebetsa. Ntle le haeba ho dumellanwe ka tsela e nngwe ha ho dumellwe ho eketsa B ka boomo mme B e setseng ≤ 0.001%. | |||||||||||||||||||||

| PSL | Boemo ba ho Romela | Sehlopha sa phaephe |

| PSL1 | Ha e ntse e phuthoa, e tloaelehile, e tloaelehile | A |

| Ha e phuthoa, e phuthoa ka mokhoa o tloaelehileng, e phuthoa ka mokhoa o itekanetseng, e phuthoa ka mokhoa o itekanetseng, e phuthoa ka mokhoa o itekanetseng, e phuthoa ka mokhoa o itekanetseng le e hatelitsoeng kapa haeba ho dumellanoa ka Q&T SMLS feela | B | |

| Ha e phuthoa, e phuthoa ka mokhoa o tloaelehileng, e phuthoa ka mokhoa o itekanetseng, e phuthoa ka mokhoa o itekanetseng, e phuthoa ka mokhoa o itekanetseng, e phuthoa ka mokhoa o itekanetseng le e halefisitsoeng | X42, X46, X52, X56, X60, X65, X70 | |

| PSL 2 | Ha e phutholohile | BR, X42R |

| Ho phutholla, ho etsa hore ho be le maemo a tloaelehileng, ho be le maemo a tloaelehileng kapa ho be le maemo a tloaelehileng le ho halefisoa | BN, X42N, X46N, X52N, X56N, X60N | |

| E timme ebile e bebofalitsoe | BQ, X42Q, X46Q, X56Q, X60Q, X65Q, X70Q, X80Q, X90Q, X100Q | |

| Thermomechanical rolled kapa thermomechanical e entsoe | BM, X42M, X46M, X56M, X60M, X65M, X70M, X80M | |

| Thermomechanical e phutholohile | X90M, X100M, X120M | |

| Ho lekana (R, N, Q kapa M) bakeng sa limaraka tsa PSL2, ke tsa sehlopha sa tšepe |

PSL1 le PSL2 li fapane ka tekanyo ea liteko hammoho le ka litšobotsi tsa tsona tsa lik'hemik'hale le tsa mechini.

PSL2 e thata ho feta PSL1 ka sebopeho sa lik'hemik'hale, thepa ea ho thaepa, teko ea tšusumetso, liteko tse sa senyeheng le tse ling.

Teko ea Tšusumetso

Ke PSL2 feela e hlokang teko ea tšusumetso: ntle le X80.

NDT: Teko e sa Senyeheng. PSL1 ha e hloke diteko tse sa senyeheng haeba ho fokotswa tekanyo. Teko e sa senyeheng e a sebetsa. PSL2 e a sebetsa.

(Teko e sa senyeheng: Teko le liteko tse sa senyeheng tekanyetsong ea API 5L li sebelisa radiographic, ultrasonic, kapa mekhoa e meng (ntle le ho senya thepa) ho lemoha liphoso le mefokolo liphaepheng.)

Sephutheloana kehangata o hlobotse, ho tlama terata ea tšepe, haholomatla.

Haeba o na le ditlhoko tse ikgethang, o ka sebedisasephutheloana se thibelang mafome, 'me e ntle le ho feta.

Mehato ea ho ela hloko bakeng sa ho paka le ho tsamaisa liphaephe tsa tšepe ea khabone

1.Pipe ea Tšepe ea API 5Le tlameha ho sireletsoa tšenyong e bakoang ke ho thulana, ho tsoa le ho sehoa nakong ea lipalangoang, polokelo le tšebeliso.

2. Ha o ntse o sebetsana le diphaephe tsa tshepe ya khabone, o lokela ho ela hloko ho phatloha, mollo, chefo le dikotsi tse ding, mme o tsamaellane le mekgwa ya ts'ebetso ya polokeho.

3. Nakong ea tšebeliso,Tšepe ea k'habone ea API 5L Pipeli lokela ho qoba ho kopana le mocheso o phahameng, mecha ea phatlalatso e senyang, jj. Haeba li sebelisoa libakeng tsena, liphaephe tsa tšepe ea carbon tse entsoeng ka thepa e khethehileng joalo ka ho hanyetsa mocheso o phahameng le ho hanyetsa ho bola li lokela ho khethoa.

4. Khetho ea phaephe ea tšepe ea khabone e lokela ho ba ea thepa e loketseng le litlhaloso ho latela lintlha tse akaretsang ho kenyeletsoa tikoloho ea ts'ebeliso, mofuta o mahareng, khatello, mocheso le tse ling.

5. Litlhahlobo le liteko tse hlokahalang li lokela ho etsoa pele phaephe ea tšepe ea khabone e sebelisoa ho paka hore boleng ba eona bo fihlela maemo a tloaelehileng.

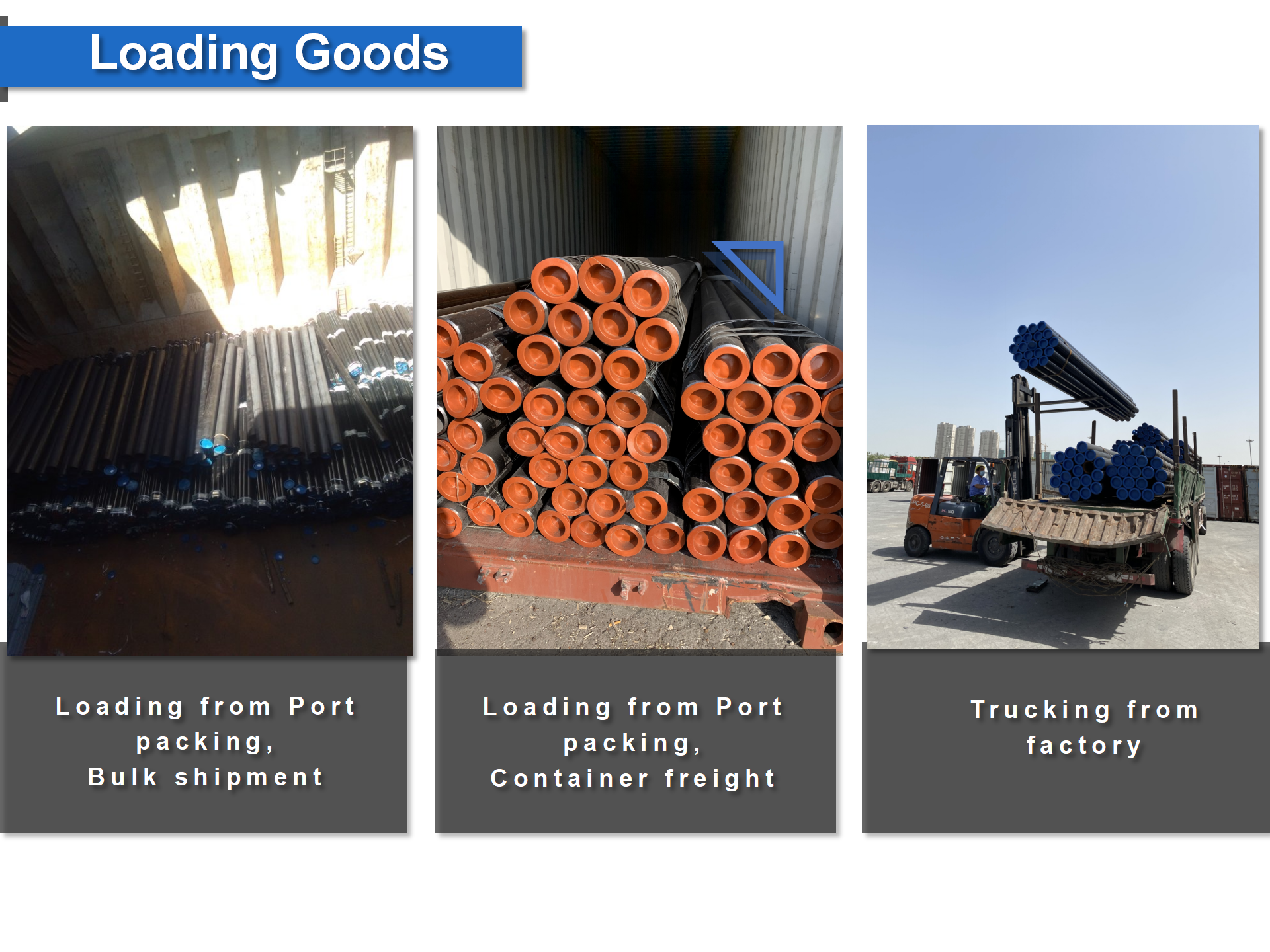

Lipalangoang:Ka potlako (Tlhahiso ea Mehlala), Sefofane, Seporo, Naha, Thomello ea Leoatle (FCL kapa LCL kapa Bongata)

P: Na ke moetsi oa UA?

K: E, re moetsi oa li-tube tsa tšepe tse potolohang motsaneng oa Daqiuzhuang, motseng oa Tianjin, Chaena.

P: Na nka fumana odara ea teko ea lithane tse 'maloa feela?

K: Ehlile. Re ka o romella thepa ka tšebeletso ea LCL. (Mojaro o fokolang oa lijana)

P: Haeba sampole e lokolohile?

K: Sampole ha e fumanehe, empa moreki o lefella thepa.

P: Na o fana ka khauta mme o etsa tiisetso ya kgwebo?

A: Re fana ka khauta ka lilemo tse 13 'me re amohela tiisetso ea khoebo.