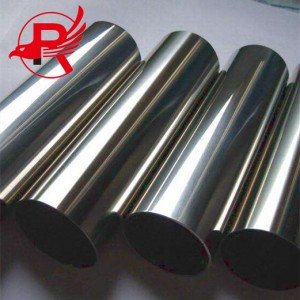

Pipe ea Tšepe e sa Khaotseng ea ASTM Ss 316 316ti 310S 309S

| tem | Pipe ea Tšepe e sa Khaotseng |

| E tloaelehileng | JIS, AiSi, ASTM, GB, DIN, EN |

| Sebaka sa Tšimoloho | Chaena |

| Lebitso la Letšoao | BORASO |

| Mofuta | Ha e na seamless / e tjheseletsa |

| Kereiti ea Tšepe | Letoto la 200/300/400, 904L S32205 (2205),S32750(2507) |

| Kopo | Indasteri ea lik'hemik'hale, lisebelisoa tsa mechini |

| Tšebeletso ea Ts'ebetso | Ho kobeha, ho tjheseletsa, ho qhibilihisa, ho phunya, ho seha, ho bopa |

| Mokhoa | E phutholohile e chesang/e batang e phutholohile |

| Melao ea tefo | L/CT/T (30% depositi) |

| Nako ea Theko | CIF CFR FOB EX-WORK |

Liphaephe tsa tšepe e sa ruseng li arotsoe ka liphaephe tse tloaelehileng tsa tšepe ea carbon, liphaephe tsa tšepe ea carbon ea boleng bo holimo, liphaephe tsa alloy, liphaephe tsa tšepe e sa ruseng, liphaephe tsa tšepe e nang le li-bearing, liphaephe tsa tšepe e sa ruseng, le liphaephe tse kopantsoeng tsa bimetallic, liphaephe tse koahetsoeng le tse koahetsoeng ho boloka litšepe tsa bohlokoa le ho fihlela litlhoko tse khethehileng. . Ho na le mefuta e mengata ea liphaephe tsa tšepe e sa ruseng tse nang le ts'ebeliso e fapaneng, litlhoko tse fapaneng tsa tekheniki, le mekhoa e fapaneng ea tlhahiso.

Hlokomela:

1. Ho etsa sampole mahala, 100% tiisetso ea boleng kamora thekiso, Tšehetsa mokhoa ofe kapa ofe oa tefo;

2. Litlhaloso tse ling kaofela tsa liphaephe tsa tšepe ea khabone e chitja lia fumaneha ho latela tlhoko ea hau (OEM & ODM)! Theko ea fektheri eo u tla e fumana ho ROYAL GROUP.

Lisebelisoa tsa lik'hemik'hale tsa Pipe ea Tšepe e sa Khaotseng

| Sebopeho sa Lik'hemik'hale % | ||||||||

| Sehlopha | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0 .15 | ≤0 .75 | 5. 5-7. 5 | ≤0.06 | ≤ 0.03 | 3.5 -5.5 | 16 .0 -18.0 | - |

| 202 | ≤0 .15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - |

| 301 | ≤0 .15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - |

| 302 | ≤0 .15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - |

| 304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0 .03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 - 15.0 | 16 .0 -1 8.0 | 2.0 -3.0 |

| 321 | ≤ 0 .08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 - 13.0 | 17.0 -1 9.0 | - |

| 630 | ≤ 0 .07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - |

| 631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - |

| 904L | ≤ 2.0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0·28.0 | 19.0-23.0 | 4.0-5.0 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19 -0. 22 | 0. 24 -0 . 26 | - |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - |

| 430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | |

Liphaephe tsa tšepe e sa ruseng li arotsoe ka mekhahlelo e 'meli: liphaephe tse se nang mohele le liphaephe tse kopantsoeng ho latela mekhoa ea tlhahiso. Liphaephe tsa tšepe tse se nang mohele li ka aroloa ka liphaephe tse phuthoang ka mocheso, liphaephe tse phuthoang ka serame, liphaephe tse huloang ka serame le liphaephe tse ntšitsoeng. Liphaephe tse huloang ka serame le tse phuthoang ka serame ke lits'ebetso tsa bobeli tsa liphaephe tsa tšepe. Ts'ebetso; liphaephe tse kopantsoeng li arotsoe ka liphaephe tse phuthoang ka seam tse otlolohileng le liphaephe tse phuthoang ka sekontiri.

Liphaephe tsa tšepe e sa ruseng li ka aroloa ka liphaephe tse chitja le liphaephe tse bōpehileng joaloka tse khethehileng ho latela libopeho tsa tsona tse tšekaletseng. Liphaephe tse bōpehileng joaloka tse khethehileng li kenyelletsa liphaephe tse khutlonnetsepa, liphaephe tsa rhombus, liphaephe tse oval, liphaephe tse nang le mahlakore a tšeletseng, liphaephe tse nang le mahlakore a mane le liphaephe tse fapaneng tse se nang moeli. Liphaephe tse bōpehileng joaloka tse khethehileng li sebelisoa haholo likarolong tse fapaneng tsa sebopeho, lisebelisoa le likarolo tsa mechine. Ha li bapisoa le liphaephe tse chitja, liphaephe tse bōpehileng joaloka tse khethehileng ka kakaretso li na le nako e kholoanyane ea ho se inertia le modulus ea karolo, 'me li na le khanyetso e kholoanyane ea ho kobeha le ho torsion, e leng se ka fokotsang boima ba sebopeho haholo le ho boloka tšepe.

Liphaephe tsa tšepe e sa ruseng li ka aroloa ka liphaephe tse lekanang le tse feto-fetohang ho latela libopeho tsa tsona tsa karolo e telele. Liphaephe tse feto-fetohang tsa karolo e fapaneng li kenyelletsa liphaephe tse tenyetsehang, liphaephe tse nang le litepisi le liphaephe tse nang le karolo e fetang nako.

1. Sephutheloana sa polasetiki

Nakong ea ho tsamaisoa ha liphaephe tsa tšepe e sa ruseng, hangata ho sebelisoa maqephe a polasetiki ho paka liphaephe. Mokhoa ona oa ho paka o molemo ho sireletsa bokaholimo ba phaephe ea tšepe e sa ruseng hore e se ke ea tsofala, ea ngoapa le ea silafala, 'me hape o bapala karolo ho haneleng mongobo, ho haneleng lerōle le ho thibela ho bola.

2. Sephutheloana sa theipi

Ho paka ka theipi ke tsela e theko e tlase, e bonolo le e bonolo ea ho paka liphaephe tsa tšepe e sa ruseng, hangata ho sebelisoa theipi e hlakileng kapa e tšoeu. Tšebeliso ea ho paka ka theipi e ke ke ea sireletsa bokaholimo ba phaephe feela, empa hape e ka matlafatsa matla a phaephe le ho fokotsa monyetla oa ho falla kapa ho sotha phaephe nakong ea lipalangoang.

3. Sephutheloana sa pallet sa lehong

Ho tsamaiseng le ho boloka liphaephe tse kholo tsa tšepe e sa ruseng, ho paka liphaephe tsa lehong ke mokhoa o sebetsang haholo. Liphaephe tsa tšepe e sa ruseng li khomaretsoe holim'a phaephe ka likhoele tsa tšepe, tse ka fanang ka tšireletso e ntle haholo le ho thibela liphaephe ho thulana, ho kobeha, ho senyeha, jj. nakong ea lipalangoang.

4. Sephutheloana sa lebokose

Bakeng sa liphaephe tse ling tse nyane tsa tšepe e sa ruseng, ho paka ka lebokose ke mokhoa o tloaelehileng haholoanyane. Molemo oa ho paka ka lebokose ke hore ho bobebe ebile ho bonolo ho ho tsamaisa. Ntle le ho sireletsa bokaholimo ba phaephe, e ka boela ea ba bonolo bakeng sa polokelo le tsamaiso.

5. Sephutheloana sa setshelo

Bakeng sa ho romela kantle ho naha liphaephe tsa tšepe e sa ruseng ka bongata bo boholo, ho paka likhonteine ke mokhoa o tloaelehileng haholo. Ho paka likhonteine ho ka netefatsa hore liphaephe li tsamaisoa ka mokhoa o sireletsehileng ntle le likotsi leoatleng, 'me ho qoba ho kheloha, ho thulana, jj. nakong ea lipalangoang.

Lipalangoang:Ka potlako (Tlhahiso ea Mehlala), Ka Sefofane, Terene, Naheng, Thomello ea Leoatleng (FCL kapa LCL kapa Bongata)

Moreki oa Rona

1. Litheko tsa hau ke life?

Litheko tsa rona li ka fetoha ho latela phepelo le lintlha tse ling tsa 'maraka. Re tla u romella lethathamo la litheko tse ntlafalitsoeng kamora ho ikopanya le k'hamphani ea hau.

re romelle bakeng sa tlhahisoleseling e batsi.

2. Na o na le bonyane ba odara e ngata?

E, re hloka hore liodara tsohle tsa machabeng li be le palo e fokolang ea odara e tsoelang pele. Haeba u batla ho rekisa hape empa ka bongata bo bonyenyane haholo, re khothaletsa hore u shebe webosaete ea rona.

3. Na o ka fana ka ditokomane tse amehang?

E, re ka fana ka boholo ba litokomane ho kenyeletsoa le Litifikeiti tsa Tlhahlobo / Tumellano; Inshorense; Tšimoloho, le litokomane tse ling tsa kantle ho naha moo ho hlokahalang.

4. Nako e tloaelehileng ea ho etella pele ke bokae?

Bakeng sa disampole, nako ea ho etella pele ke matsatsi a ka bang 7. Bakeng sa tlhahiso e kholo, nako ea ho etella pele ke matsatsi a 5-20 kamora ho fumana tefo ea depositi. Linako tsa ho etella pele li qala ho sebetsa ha

(1) re fumane depositi ea hau, 'me (2) re na le tumello ea hau ea ho qetela bakeng sa lihlahisoa tsa hau. Haeba linako tsa rona tsa ho etella pele li sa sebetse le nako ea hau ea ho qetela, ka kopo sheba litlhoko tsa hau mabapi le thekiso ea hau. Maemong 'ohle re tla leka ho fihlela litlhoko tsa hau. Maemong a mangata re khona ho etsa joalo.

5. Ke mefuta efe ea mekhoa ea ho lefa eo u e amohelang?

30% esale pele ka T/T, 70% e tla ba pele ho thomello ea motheo ho FOB; 30% esale pele ka T/T, 70% khahlanong le kopi ea BL ea motheo ho CIF.