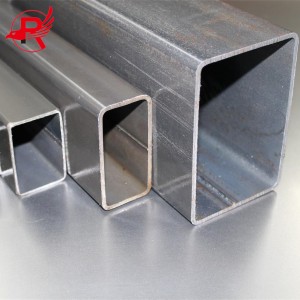

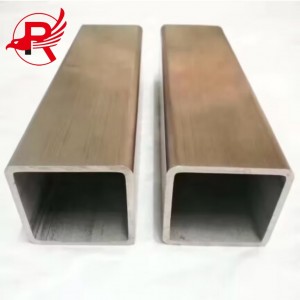

Erw Welded & Seamless Hot Rolled Black Carbon Steel Square Rectangular Pipe Tube

Khabone Tšepe e khutlonnetsepa Pipeke motsoako oa tšepe-khabone o nang le khabone ea0.0218% ho isa ho 2.11%. E boetse e bitsoa tšepe ea khabone. Ka kakaretso e boetse e na le karolo e nyane ea silicon, manganese, sebabole, phosphorus. Ka kakaretso, ha khabone e le ngata ka har'a tšepe ea khabone, ho ba thata le matla a ho feta, empa polasetiki e tlaase.

| Ntho | Tlhaloso / Tlhaloso |

| Maemo a Thepa | GB/T (Chaena), EN 10210 / EN 10219 (Yuropa), ASTM A500 / ASTM A513 (USA) |

| Litekanyo | Bolelele: 6–12 m (e ka fetoloang) |

| Bophara / Bophahamo: 20×20 mm – 500×500 mm | |

| Botenya ba Lebota: 1.5–20 mm | |

| Mokhoa oa Tlhahiso | E phutholohile ka ho chesa, E entsoe ka serame, Ha e na sekoli, kapa e kopantsoe |

| Qetello ea Bokaholimo | E ntšo, e bentšitsoeng ka khalase, e pentiloe, e bentšitsoeng |

| Litšebeletso tsa Ts'ebetso | Ho seha, ho tjheka, ho kobeha, ho tjheseletsa, ho kenya khoele, ho etsa dintho ka tsela e ikgethang |

| Tlhahlobo le Teko | Tlhahlobo ea litekanyo, Teko ea thepa ea mechini, Teko ea ho bōptjoa ha lik'hemik'hale, Teko ea Ultrasonic kapa ea Hydrostatic |

| Sephutheloana | E phuthetsoe ka maqhama a tšepe, mabokose a lehong, ho phuthela ka polasetiki, kapa ho paka ka mokhoa o ikhethileng ho latela tlhoko ea moreki |

Thephaephe e khutlonnetsepae sebelisoa haholo kahong, mechineng, kahong ea likepe, motlakaseng, temong le temong ea liphoofolo, polokelong, tšireletsong ea mollo, lisebelisoa tsa lapeng le liindastering tse ling, 'me ho ka thoe ke tšepe ea bohlokoa bakeng sa nts'etsopele ea indasteri ea sejoale-joale.

Hlokomela:

1. Mahala ho etsa disampole,100%netefatso ea boleng ba kamora thekiso, letšehetso bakeng sa mokhoa ofe kapa ofe oa ho lefa;

2. Litlhaloso tse ling kaofela tsaliphaephe tsa tšepe ea carbone ka fanoa ho latela litlhoko tsa hau (OEM le ODM)! U tla fumana theko ea fektheri ea mehleng ho tsoa ho Royal Group.

3. Setsebiltšebeletso ea tlhahlobo ea sehlahisoa,khotsofalo e phahameng ea bareki.

4. Potoloho ea tlhahiso e khutšoanyane, 'me80% ea liodara e tla tlisoa esale pele.

5. Litšoantšo ke tsa lekunutu 'me kaofela ke tsa bareki.

1. Litlhoko: litokomane kapa litšoantšo

2. Netefatso ea morekisi: netefatso ea setaele sa sehlahisoa

3. Netefatsa mokhoa oa ho iketsetsa lintho: netefatsa nako ea tefo le nako ea tlhahiso (depositi ea tefo)

4. Tlhahiso ha ho hlokahala: ho emetse netefatso ea rasiti

5. Netefatsa thomello: lefa tjhelete e setseng mme o e tlise

6. Netefatsa rasiti

Ts'ebetso ea tlhahiso ea liphaephe tsa tšepe tse tjhitliloeng ka sekwere hangata e kenyelletsa mehato e latelang ea mantlha, 'me ts'ebetso e itseng e ka fetoloa ho latela lisebelisoa tsa tlhahiso le litlhaloso tsa sehlahisoa:

1. Tokisetso ea Lisebelisoa tse Tala

Khetho ea mothapo oa tšepe: Sebelisa mothapo oa tšepe o phutholohileng ka ho chesa kapa o batang e le thepa e tala, 'me u khethe thepa e loketseng ea mothapo oa tšepe (joalo ka tšepe ea khabone, tšepe ea motsoako, jj.) ho latela litlhaloso tsa sehlahisoa (joalo ka botenya ba lebota, boholo).

Ho phutholla le ho batalatsa: Phutholla moqomo oa tšepe o kobehileng ka har'a mochini o phuthollang, 'me u sebelise mochini o phuthollang ho felisa sebopeho sa leqhubu kapa ho kobeha ha moqomo oa tšepe ho netefatsa hore bokaholimo bo bataletse.

2. Ho theha

Ho kobeha pele le ho bopeha ka thata: Moqomo wa tshepe o kobeha butle-butle ka disete tse ngata tsa dirolara ho etsa profaele ya pele e kgutlonnetsepa. Hangata theknoloji ya "ho kobeha ka serame" e sebediswa ho qoba ho thatafala ha thepa.

Ho bopa ka boqhetseke: Sebelisa dibopeho tse nepahetseng ho lokisa sebopeho ho netefatsa ho nepahala ha phala ya tshepe e sekwere (jwalo ka bolelele ba lehlakore, ho otloloha).

3. Ho tjheseletsa

Ho tjheseletsa kganyetso ya maqhubu a hodimo (ERW):

Lokisa mathoko a mothapo wa tshepe o bopilweng mme o futhumatse mathoko a mothapo wa tshepe ho ya boemong bo qhibilihisitsweng ka motlakase o phahameng.

Kenya khatello ho kopanya mathoko ho etsa weld e tswelang pele.

Ho Welding ea Arc e Kenelletseng ka Tlase (SAW):

E sebelisoa liphaepheng tsa tšepe tse bophara bo boholo kapa tse teteaneng, phallo e koahetsoe ho weld, 'me terata ea welding le thepa ea motheo li qhibilihisoa ke arc ho etsa weld.

4. Ts'ebetso ea ho Cheseletsa

Ho tlosa ditshila: Sebedisa sehahi sa ho sila kapa lebili la ho sila ho tlosa ditshila hodima bokahodimo ba ka hare le ba ka ntle ba weld ho netefatsa hore bokahodimo bo boreleli.

Ho lemoha diphoso tsa ho weld: Sebedisa ultrasound kapa X-ray ho lemoha diphoso tsa ka hare ho weld (tse kang masoba le ho hloka ho kopana).

5. Ho lekanya le ho otlolla

Mochini oa boholo: Lokisa ho nepahala ha phala ea tšepe ka ho e phutholla ho netefatsa hore bolelele ba lehlakore le ho chitja li fihlela maemo.

Mochini o otlollang: Tlosa ho kobeha ha phaephe ea tšepe nakong ea ts'ebetso ea ho etsa kapa ea ho tjheseletsa.

6. Ho Pholisa le ho Seha

Ho Pholisa: Sebelisa ho pholisa ka metsi kapa ho pholisa ka moea ho fokotsa mocheso oa phaephe ea tšepe ho qoba ho fetoha ha mocheso.

Ho seha: Sebelisa sakha e fofang kapa sakha e chitja ho seha phaephe ea tšepe e tsoelang pele ka bolelele bo hlokahalang (joalo ka limithara tse 6, limithara tse 12).

7. Kalafo ea Bokaholimo

Ho pickling/phosphate: tlosa sekala sa oxide ea bokaholimo le litšila ho itokisetsa kalafo e latelang.

Ho penta ka galvani kapa ho penta: ho ntlafatsa ho hanyetsa ho bola ha liphaephe tsa tšepe ka ho li kenya ka galvaning ka ho chesa kapa ho fafatsa pente e thibelang mafome.

8. Tlhahlobo ea Boleng

Tekanyo ea boholo: hlahloba liparamente tse kang bolelele ba lehlakore, botenya ba lebota, bolelele, jj.

Teko ea thepa ea mechini: teko ea ho tsitlella, teko ea tšusumetso, jj. ho netefatsa matla le ho tiea ha thepa.

Tlhahlobo ea ponahalo: ka pono kapa ka lisebelisoa tse iketsang ho lemoha liphoso tsa bokaholimo (tse kang mengoapo, matheba).

9. Sephutheloana le Polokelo

Sephutheloana: sephutheloana, leibole, kapa sebelisa thepa e sa keneleng mongobo bakeng sa ho paka ho latela litlhoko tsa bareki.

Polokelo: boloka ka lihlopha ho qoba ho fetoha kapa mafome a bakoang ke khatello e matla kapa tikoloho e mongobo.

Sephutheloana hangata ha se na letho, se tlama terata ea tšepe, se matla haholo.

Haeba o na le litlhoko tse khethehileng, o ka sebelisa sephutheloana se thibelang mafome, 'me se be setle haholoanyane.

Mehato ea ho ela hloko bakeng sa ho paka le ho tsamaisa liphaephe tsa tšepe ea khabone

1. Liphaephe tsa tšepe ea khabone li tlameha ho sireletsoa tšenyong e bakoang ke ho thulana, ho tsoa le ho sehoa nakong ea lipalangoang, polokelo le tšebeliso.

2. Ha o sebedisaPipe ea Tšepe ea A36, o lokela ho latela mekgwa e tsamaellanang ya ts'ebetso ya polokeho mme o ele hloko ho thibela ho phatloha, mollo, chefo le dikotsi tse ding.

3. Nakong ea tšebeliso, liphaephe tsa tšepe ea khabone li lokela ho qoba ho kopana le mocheso o phahameng, mecha ea phatlalatso e senyang, jj. Haeba li sebelisoa libakeng tsena, liphaephe tsa tšepe ea khabone tse entsoeng ka thepa e khethehileng joalo ka ho hanyetsa mocheso o phahameng le ho hanyetsa ho bola li lokela ho khethoa.

4. Ha o kgethaPipe ea Tšepe ea A53, liphaephe tsa tšepe ea khabone tse entsoeng ka thepa le litlhaloso tse loketseng li lokela ho khethoa ho latela lintlha tse akaretsang tse kang tikoloho ea tšebeliso, thepa e mahareng, khatello, mocheso le lintlha tse ling.

5. Pele ho sebelisoa liphaephe tsa tšepe ea khabone, ho lokela ho etsoa liteko le liteko tse hlokahalang ho netefatsa hore boleng ba tsona bo fihlela litlhoko.

Lipalangoang:Ka potlako (Tlhahiso ea Mehlala), Ka Sefofane, Terene, Naheng, Thomello ea Leoatleng (FCL kapa LCL kapa Bongata)

Litšebeletso

Re Ikhetha ka ho Sebetsa ka Lintho tse Ikhethileng.

Sehlopha sa rona se nang le boiphihlelo se tla seha, se bope le ho tjheseletsa thepa ho ya ka ditlhoko tsa hao. Re sebaka se le seng seo o ka se rekang: Odara dihlahiswa tseo o di hlokang, o di etse hore di be tse ikgethileng ho ya ka ditlhoko tsa hao, mme o fumane thomello e potlakileng le ya mahala. Sepheo sa rona ke ho fokotsa mosebetsi bakeng sa hao—ho o bolokela nako le tjhelete.

Ho saga, ho kuta le ho seha malakabe

Re na le li-bandsaw tse tharo sebakeng seo tse khonang ho seha li-miter. Re seha poleiti ea malakabe e teteaneng ho fihlela ho 4½", 'me Cincinnati Shear ea rona e khona ho seha lakane e tšesaane ea gauge ea 22 le e boima ba ¼” sekwere le e nepahetseng. Haeba u hloka thepa e sehiloeng kapele le ka nepo, re fana ka tšebeletso ea letsatsi le le leng.

Ho tjheseletsa

Mochini oa rona oa ho Welda oa Lincoln 255 MIG o lumella ba tjheseletsang ba rona ba nang le boiphihlelo ho tjheseletsa mofuta ofe kapa ofe oa litšiea tsa ntlo kapa litšepe tse fapaneng tseo u li hlokang.

Ho phunya lesoba

Re ikhethile ka ho sebelisa lipoleiti tsa tšepe tse phaphametseng. Sehlopha sa rona se ka hlahisa masoba a manyane a bophara ba ⅛" le bophara ba 4¼". Re na le mechine ea ho phunya ea makenete ea Hougen le Milwaukee, mechine ea ho phunya ea letsoho le ea ho sebetsa ka tšepe, le mechine ea ho phunya ea CNC e iketsang le mechine ea ho phunya.

Kontraka e nyenyane

Haeba ho hlokahala, re tla sebetsa le e mong oa balekane ba rona ba bangata ba tsoang naheng ka bophara ho u tlisetsa sehlahisoa sa boleng bo holimo le se theko e tlaase. Litšebelisano tsa rona li netefatsa hore odara ea hau e sebetsoa ka katleho ke litsebi tse nang le boiphihlelo bo boholo indastering.

P: Na ke moetsi oa UA?

K: E, re moetsi. Re na le fektheri ea rona e fumanehang Motsaneng oa Daqiuzhuang, Tianjin City, Chaena. Ntle le moo, re sebelisana le likhoebo tse ngata tsa mmuso, tse kang BAOSTEEL, SHOUGANG GROUP, SHAGANG GROUP, jj.

P: Na nka fumana odara ea teko ea lithane tse 'maloa feela?

K: Ehlile. Re ka o romella thepa ka tshebeletso ya LCL. (Mojaro o fokolang wa dikontenara)

P: Na o na le boleng bo phahameng ba tefo?

A: Bakeng sa odara e kholo, matsatsi a 30-90 L/C a ka amoheleha.

P: Haeba sampole e lokolohile?

K: Sampole ha e fumanehe, empa moreki o lefella thepa.

P: Na o fana ka khauta mme o etsa tiisetso ya kgwebo?

A: Re bafani ba likhau tsa khauta ka lilemo tse 13 'me re fana ka tiisetso ea khoebo.