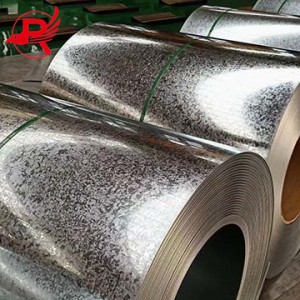

Koili ea Tšepe e Chesang e Koahetsoeng ka Mocheso ea JIS SGCC Galvanized Steel Coil

Koili e betliloeng, lakane e tšesaane ea tšepe e qoelisoang ka bateng ea zinki e qhibilihisitsoeng ho etsa hore bokaholimo ba eona bo khomarele lera la zinki. Hona joale, e hlahisoa haholo-holo ka mokhoa o tsoelang pele oa ho galvanizing, ke hore, poleiti ea tšepe e phuthiloeng e qoelisoa ka ho tsoelang pele ka bateng ka zinki e qhibilihisitsoeng ho etsa poleiti ea tšepe e qhibilihisitsoeng; Lakane ea tšepe e qhibilihisitsoeng ka alloy. Mofuta ona oa poleiti ea tšepe o boetse o etsoa ka mokhoa oa ho qoelisa ka ho chesang, empa o futhumatsoa ho fihlela ho 500 ℃ hang ka mor'a hore o tsoe ka tankeng, e le hore o ka etsa seaparo sa alloy sa zinki le tšepe. Coil ena ea galvanized e na le ho tiea ho hotle ha ho koahela le ho kopanya. Likhoele tsa galvanized li ka aroloa ka likhoele tsa galvanized tse qhibilihisitsoeng ka ho chesa le likhoele tsa galvanized tse qhibilihisitsoeng ka ho bata, tse sebelisoang haholo kahong, lisebelisoa tsa ntlo, likoloi, lijana, lipalangoang le indastering ea malapa. Haholo-holo, kaho ea sebopeho sa tšepe, tlhahiso ea likoloi, tlhahiso ea polokelo ea tšepe le liindasteri tse ling. Tlhoko ea indasteri ea kaho le indasteri ea mabone ke 'maraka o moholo oa coil ea galvanized, e etsang hoo e ka bang 30% ea tlhoko ea lakane ea galvanized.

Thekhoele ea tšepe ea galvanizedTs'ebetso ea tlhahiso e ka kenyelletsa mehato e latelang:

1. Tokisetso ea thepa e tala: Ts'ebetso e qala ka ho khetha tšepe ea boleng bo holimo, e lateloe ke ho hloekisa ho tlosa litšila life kapa life tse ka bakang liphoso sehlahisoa sa ho qetela.

2. Ho Rotha ka Serame: Tšepe e hloekisitsoeng e fetisoa ka har'a letoto la meqolo ho fokotsa botenya ba eona le ho ntlafatsa qetello ea eona.

3. Annealing: Karolo ea tšepe e futhumatsoa ka sebōping se laoloang sa sepakapaka ho e nolofatsa le ho etsa hore ho be bonolo ho e khella ka galvani.

4. Ho lahla likhalase: Sekotwana sa tshepe se qoelisoa ka bateng ya zinki e qhibilihisitsweng ho e tlotsa ka lera la zinki ho thibela ho bola. Tshebetso ena e bitswa hot dip galvanizing.

5. Ho pholisa: Tšepe e nang le galvanized e phodiswa mochesong wa kamore pele e kobeha.

6. Ho Lekanya Khatello: Koili ebe e feta ka har'a sesebelisoa sa ho lekanya khatello, se tlosang khatello efe kapa efe e setseng le ho netefatsa hore koili e na le sebopeho se bataletseng le se tsitsitseng.

7. Taolo ea Boleng: Qetellong, dikhoele tsa tshepe tse nang le galvanized di a hlahlojwa bakeng sa diphoso dife kapa dife mme di a lekoa ho netefatsa hore di fihlela ditlhoko tse hlokahalang.

Likhoele tsa tšepe tse entsoeng ka galvanized tse felileng li sebelisoa lits'ebetsong tse fapaneng ho kenyeletsoa le indasteri ea kaho, ea likoloi le ea motlakase.

1. Ho Hanela Mafome: Ho lahla mafome ka galvanizing ke mokhoa o theko e tlase le o sebetsang oa ho thibela mafome o atisang ho sebelisoa. Hoo e ka bang halofo ea tlhahiso ea zinki lefatšeng e sebelisoa bakeng sa ts'ebetso ena. Zinc ha e thehe feela lera le teteaneng la tšireletso holim'a tšepe, empa hape e na le phello ea tšireletso ea cathodic. Ha lesela la zinki le senyehile, le ntse le ka thibela mafome a thepa e thehiloeng tšepeng ka tšireletso ea cathodic.

2. Tshebetso e Ntle ea ho Koba le ho Welding: Tšepe e nang le khabone e tlase e sebelisoa haholo, e hlokang ho koba ho batang hantle, ts'ebetso ea ho welding le ts'ebetso e itseng ea ho hatakela

3. Ho bonahatsa khanya: ho bonahatsa khanya haholo, e leng se etsang hore e be mokoallo oa mocheso

4. Seaparo se na le Matla a Matla, 'me seaparo sa zinki se etsa sebopeho se ikhethang sa tšepe, se ka mamellang tšenyo ea mechini nakong ea lipalangoang le tšebeliso.

Likhoele tsa Tšepe tse Khantšitsoeng ka GalvanizedLihlahisoa li sebelisoa haholo-holo kahong, indastering e bobebe, likoloing, temong, temong ea liphoofolo, botšoasi ba litlhapi, khoebong le liindastering tse ling. Indasteri ea kaho e sebelisoa haholo-holo ho etsa liphanele tsa marulelo tse thibelang mafome le li-grating tsa marulelo bakeng sa mehaho ea liindasteri le ea sechaba; Indastering e bobebe, e sebelisoa ho etsa likhetla tsa lisebelisoa tsa ntlo, li-chimney tsa sechaba, lisebelisoa tsa kichineng, jj. Indastering ea likoloi, e sebelisoa haholo-holo ho etsa likarolo tsa likoloi tse sa senyeheng mafome, jj; Temo, tlhokomelo ea liphoofolo le botšoasi ba litlhapi li sebelisoa haholo-holo e le polokelo ea lijo le lipalangoang, lisebelisoa tsa ho sebetsana le nama le lihlahisoa tsa metsing, jj; E sebelisoa haholo-holo bakeng sa polokelo le lipalangoang tsa thepa le lisebelisoa tsa ho paka.

| Lebitso la sehlahisoa | Khoele ea tšepe e betliloeng |

| Khoele ea tšepe e betliloeng | ASTM,EN,JIS,GB |

| Sehlopha | Dx51D, Dx52D, Dx53D, DX54D, S220GD, S250GD, S280GD, S350GD, S350GD, S550GD; SGCC, SGHC, SGCH, SGH340, SGH400, SGH440, SGH490, SGH540, SGCD1, SGCD2, SGCD3, SGC340, SGC340 , SGC490, SGC570; SQ CR22 (230), SQ CR22 (255), SQ CR40 (275), SQ CR50 (340), SQ CR80(550), CQ, FS, DDS, EDDS, SQ CR33 (230), SQ CR37 (255), SQCR40 (275), SQ CR50 (340), SQ CR80 (550); kapa Tlhokahalo ea Moreki |

| Botenya | 0.10-2mm e ka fetoloa ho latela tlhoko ea hau |

| Bophara | 600mm-1500mm, ho latela tlhoko ea moreki |

| Tekheniki | Kelara e Chesang e Chesang |

| Sekoahelo sa Zinki | 30-275g/m2 |

| Phekolo ea Bokaholimo | Ho ntsha oli, ho tiisa ka lacquer, ho fosfate, ho se alafatsoe |

| Bokaholimo | spangle e tloaelehileng, spangle ea misi, e khanyang |

| Boima ba koili | Tone ea 2-15metric ka coil |

| Sephutheloana | Pampiri e sa keneleng metsi ke sephutheloana sa kahare, tšepe e nang le galvanized kapa lakane ea tšepe e koahetsoeng ke sephutheloana sa kantle, poleiti ea tšireletso ea lehlakore, ebe e phuthetsoe ka lebanta la tšepe tse supileng.kapa ho latela tlhoko ea moreki |

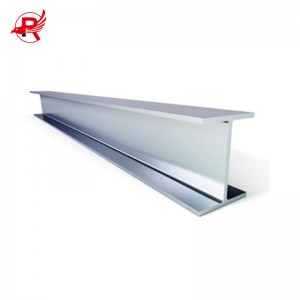

| Kopo | kaho ea sebopeho, grating ea tšepe, lisebelisoa |

1. Litheko tsa hau ke life?

Litheko tsa rona li ka fetoha ho latela phepelo le lintlha tse ling tsa 'maraka. Re tla u romella lethathamo la litheko tse ntlafalitsoeng kamora ho ikopanya le k'hamphani ea hau.

re romelle bakeng sa tlhahisoleseling e batsi.

2. Na o na le bonyane ba odara e ngata?

E, re hloka hore liodara tsohle tsa machabeng li be le palo e fokolang ea odara e tsoelang pele. Haeba u batla ho rekisa hape empa ka bongata bo bonyenyane haholo, re khothaletsa hore u shebe webosaete ea rona.

3. Na o ka fana ka ditokomane tse amehang?

E, re ka fana ka boholo ba litokomane ho kenyeletsoa le Litifikeiti tsa Tlhahlobo / Tumellano; Inshorense; Tšimoloho, le litokomane tse ling tsa kantle ho naha moo ho hlokahalang.

4. Nako e tloaelehileng ea ho etella pele ke bokae?

Bakeng sa disampole, nako ea ho etella pele ke matsatsi a ka bang 7. Bakeng sa tlhahiso e kholo, nako ea ho etella pele ke matsatsi a 5-20 kamora ho fumana tefo ea depositi. Linako tsa ho etella pele li qala ho sebetsa ha

(1) re fumane depositi ea hau, 'me (2) re na le tumello ea hau ea ho qetela bakeng sa lihlahisoa tsa hau. Haeba linako tsa rona tsa ho etella pele li sa sebetse le nako ea hau ea ho qetela, ka kopo sheba litlhoko tsa hau mabapi le thekiso ea hau. Maemong 'ohle re tla leka ho fihlela litlhoko tsa hau. Maemong a mangata re khona ho etsa joalo.

5. Ke mefuta efe ea mekhoa ea ho lefa eo u e amohelang?

30% esale pele ka T/T, 70% e tla ba pele ho thomello ea motheo ho FOB; 30% esale pele ka T/T, 70% khahlanong le kopi ea BL ea motheo ho CIF.