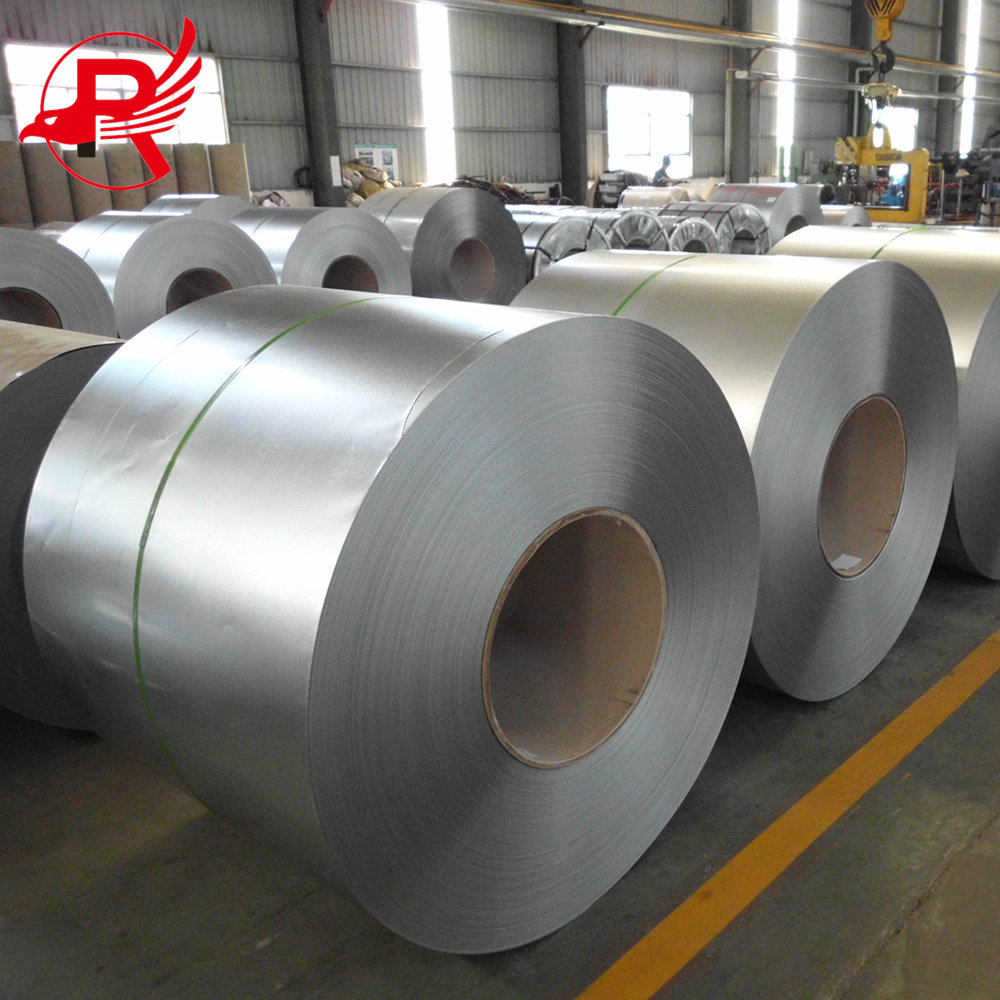

Khoele ea Tšepe e Koahetsoeng ka Zinki DX51D+z e Galalitsoeng Bakeng sa Letlapa la Tšepe le Tšepe le Senyehileng la Marulelo a Tšepe

Koili e betliloeng, lakane e tšesaane ea tšepe e qoelisoang ka bateng ea zinki e qhibilihisitsoeng ho etsa hore bokaholimo ba eona bo khomarele lera la zinki. Hona joale, e hlahisoa haholo-holo ke ts'ebetso e tsoelang pele ea ho galvanizing, ke hore, poleiti ea tšepe e phuthiloeng e qoelisoa ka ho tsoelang pele ka bateng ka zinki e qhibilihisitsoeng ho etsa poleiti ea tšepe e qhibilihisitsoeng; Lakane ea tšepe e qhibilihisitsoeng ka alloy. Mofuta ona oa poleiti ea tšepe o boetse o etsoa ka mokhoa oa ho qoelisa ka ho chesang, empa o futhumatsoa ho fihlela ho 500 ℃ hang ka mor'a hore o tsoe ka tankeng, e le hore o ka etsa seaparo sa alloy sa zinki le tšepe. Coil ena ea galvanized e na le ho tiea ho hotle ha ho roala le ho tjheseletsa. Likhoele tsa galvanized li ka aroloa ka likhoele tsa galvanized tse qhibilihisitsoeng ka ho chesa le tse qhibilihisitsoeng ka ho bata tse qhibilihisitsoeng ka ho chesa.Likhoele tsa Tšepe tse Gantšitsoeng, tse sebediswang haholoholo kahong, disebedisweng tsa ka tlung, dikoloi, dikontenareng, dipalangwang le diindastering tsa ka tlung. Haholo-holo, kaho ya meaho ya tshepe, tlhahiso ya dikoloi, tlhahiso ya polokelo ya tshepe le diindasteri tse ding. Tlhoko ya indasteri ya kaho le indasteri ya mabone ke mmaraka o ka sehloohong wa coil ya galvanized, e etsang hoo e ka bang 30% ya tlhokeho ya lakane ya galvanized.

1. Khanyetso ea ho Sila:Sekhoele sa Tšepe se betliloengke mokhoa o theko e tlase le o sebetsang oa thibelo ea mafome o atisang ho sebelisoa. Hoo e ka bang halofo ea tlhahiso ea zinki lefatšeng e sebelisoa bakeng sa ts'ebetso ena. Zinki ha e thehe feela lera le teteaneng la tšireletso holim'a tšepe, empa hape e na le phello ea tšireletso ea cathodic. Ha lesela la zinki le senyehile, le ntse le ka thibela ho senyeha ha thepa e thehiloeng tšepeng ka tšireletso ea cathodic.

2. Tshebetso e Ntle ea ho Koba le ho Welding: Tšepe e nang le khabone e tlase e sebelisoa haholo, e hlokang ho koba ho batang hantle, ts'ebetso ea ho welding le ts'ebetso e itseng ea ho hatakela

3. Ho bonahatsa khanya: ho bonahatsa khanya haholo, e leng se etsang hore e be mokoallo oa mocheso

4. Seaparo se na le Matla a Matla, 'me seaparo sa zinki se etsa sebopeho se ikhethang sa tšepe, se ka mamellang tšenyo ea mechini nakong ea lipalangoang le tšebeliso.

Likhoele tsa Tšepe tse Khantšitsoeng ka GalvanizedLihlahisoa li sebelisoa haholo-holo kahong, indastering e bobebe, likoloing, temong, temong ea liphoofolo, botšoasi ba litlhapi, khoebong le liindastering tse ling. Indasteri ea kaho e sebelisoa haholo-holo ho etsa liphanele tsa marulelo tse thibelang mafome le li-grating tsa marulelo bakeng sa mehaho ea liindasteri le ea sechaba; Indastering e bobebe, e sebelisoa ho etsa likhetla tsa lisebelisoa tsa ntlo, li-chimney tsa sechaba, lisebelisoa tsa kichineng, jj. Indastering ea likoloi, e sebelisoa haholo-holo ho etsa likarolo tsa likoloi tse sa senyeheng mafome, jj; Temo, tlhokomelo ea liphoofolo le botšoasi ba litlhapi li sebelisoa haholo-holo e le polokelo ea lijo le lipalangoang, lisebelisoa tsa ho sebetsana le nama le lihlahisoa tsa metsing, jj; E sebelisoa haholo-holo bakeng sa polokelo le lipalangoang tsa thepa le lisebelisoa tsa ho paka.

| Lebitso la sehlahisoa | Khoele ea tšepe e betliloeng |

| Khoele ea tšepe e betliloeng | ASTM,EN,JIS,GB |

| Sehlopha | Dx51D, Dx52D, Dx53D, DX54D, S220GD, S250GD, S280GD, S350GD, S350GD, S550GD; SGCC, SGHC, SGCH, SGH340, SGH400, SGH440, SGH490, SGH540, SGCD1, SGCD2, SGCD3, SGC340, SGC340 , SGC490, SGC570; SQ CR22 (230), SQ CR22 (255), SQ CR40 (275), SQ CR50 (340), SQ CR80(550), CQ, FS, DDS, EDDS, SQ CR33 (230), SQ CR37 (255), SQCR40 (275), SQ CR50 (340), SQ CR80 (550); kapa Tlhokahalo ea Moreki |

| Botenya | 0.10-2mm e ka fetoloa ho latela tlhoko ea hau |

| Bophara | 600mm-1500mm, ho latela tlhoko ea moreki |

| Tekheniki | Kelara e Chesang e Chesang |

| Sekoahelo sa Zinki | 30-275g/m2 |

| Phekolo ea Bokaholimo | Ho ntsha oli, ho tiisa ka lacquer, ho fosfate, ho se alafatsoe |

| Bokaholimo | spangle e tloaelehileng, spangle ea misi, e khanyang |

| Boima ba koili | Tone ea 2-15metric ka coil |

| Sephutheloana | Pampiri e sa keneleng metsi ke sephutheloana sa kahare, tšepe e nang le galvanized kapa lakane ea tšepe e koahetsoeng ke sephutheloana sa kantle, poleiti ea tšireletso ea lehlakore, ebe e phuthetsoe ka lebanta la tšepe tse supileng.kapa ho latela tlhoko ea moreki |

| Kopo | kaho ea sebopeho, grating ea tšepe, lisebelisoa |

P: Na ke moetsi oa UA?

K: E, re moetsi. Re na le fektheri ea rona e Tianjin City, Chaena.

P: Na nka fumana odara ea teko ea lithane tse 'maloa feela?

K: Ehlile. Re ka o romella thepa ka tšebeletso ea LCL. (Mojaro o fokolang oa lijana)

P: Haeba sampole e lokolohile?

K: Sampole ha e fumanehe, empa moreki o lefella thepa.

P: Na o fana ka khauta mme o etsa tiisetso ya kgwebo?

K: Re fana ka khauta ka lilemo tse supileng 'me re amohela tiisetso ea khoebo.