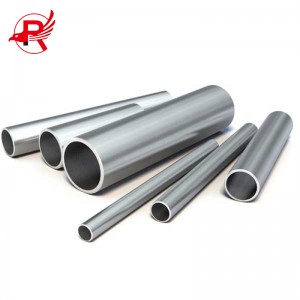

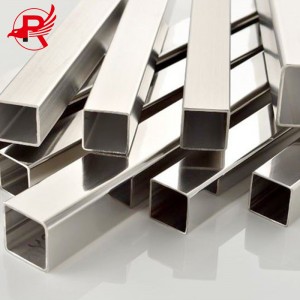

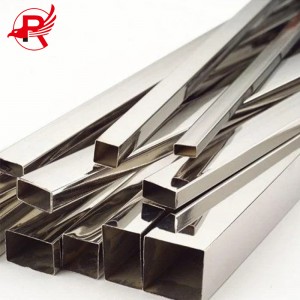

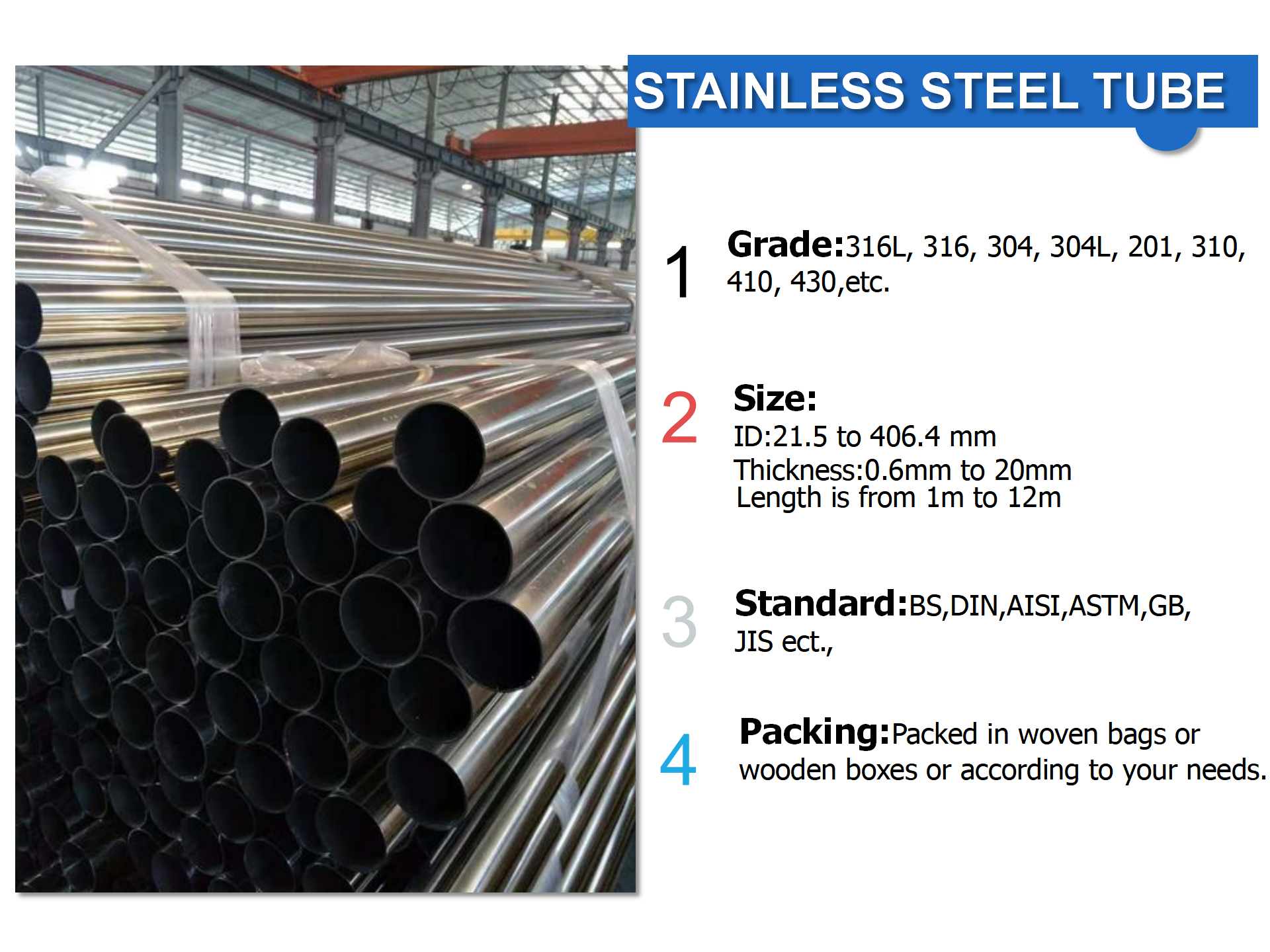

Customized 201 202 301 304 304L 321 316 316L Stainless Steel Welded Pipe

| Lebitso la Sehlahiswa | Tšepe e se nang tšepe Peipi e pota-potileng |

| Standard | ASTM AISI DIN, EN, GB, JIS |

| Kereiti ea tšepe

| 200 Series: 201,202 |

| 300 Series: 301,304,304L,316,316L,316Ti,317L,321,309s,310s | |

| 400 Series: 409L,410,410s,420j1,420j2,430,444,441,436 | |

| Duplex Steel: 904L,2205,2507,2101,2520,2304 | |

| Kantle Diameter | 6-2500mm (joalokaha ho hlokahala) |

| Botenya | 0.3mm-150mm (ho hlokahala) |

| Bolelele | 2000mm/2500mm/3000mm/6000mm/12000mm(joalokaha ho hlokahala) |

| Mokhoa | Seamless |

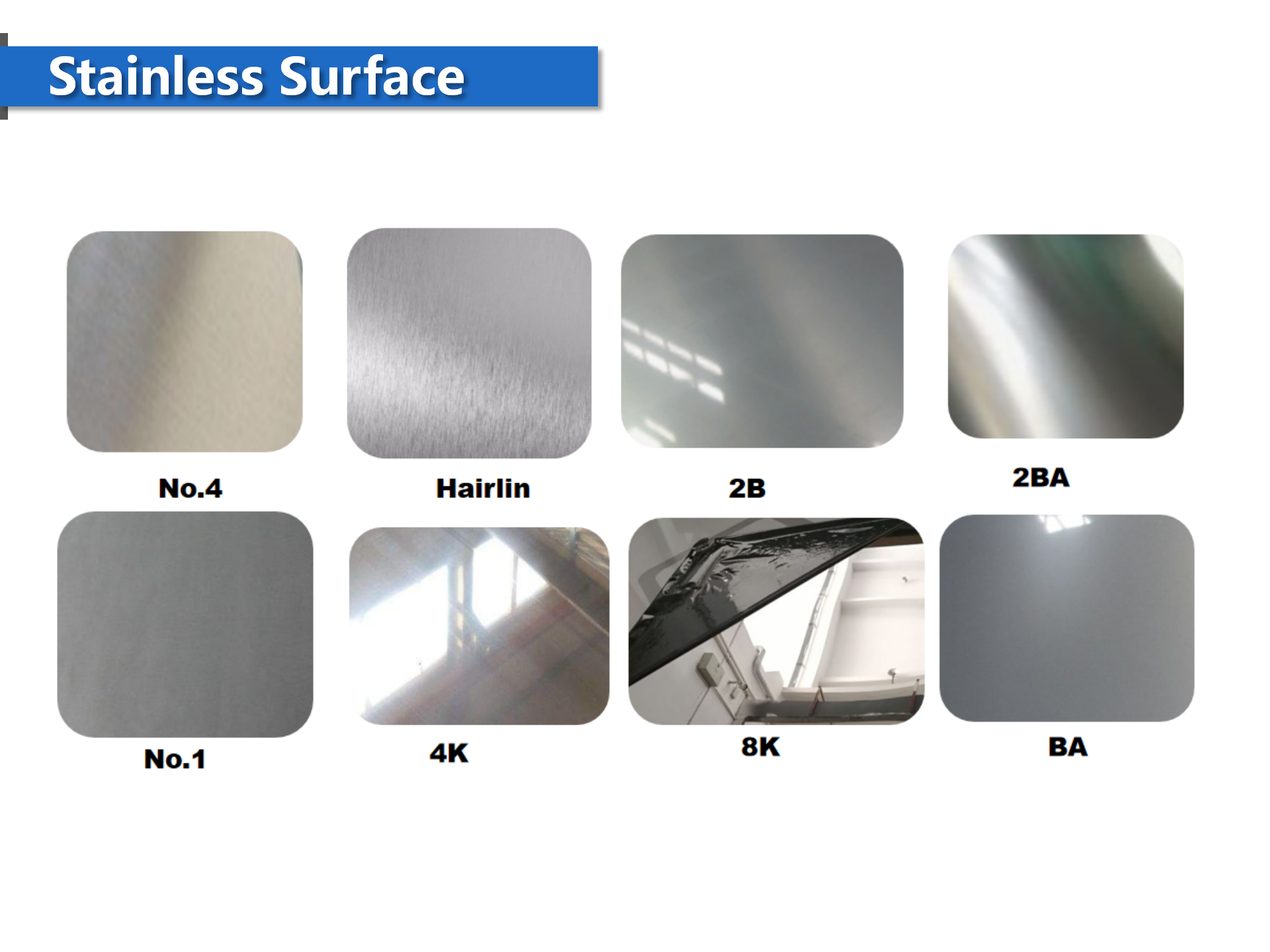

| Bokaholimo | No.1 2B BA 6K 8K Seipone No.4 HL |

| Mamello | ±1% |

| Melao ea Theko | FOB, CFR, CIF |

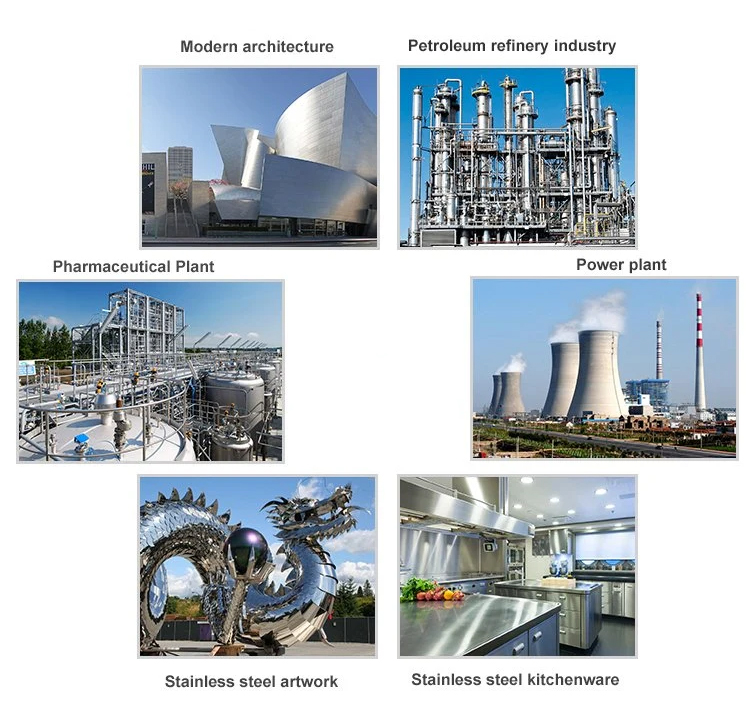

Pipe ea tšepe e sa hloekang ke mofuta oa tšepe e sekoti e telele, e sebelisoang haholo liphaepheng tsa lipalangoang tsa indasteri tse kang peterole, indasteri ea lik'hemik'hale, phekolo ea meriana, lijo, indasteri e khanyang, sesebelisoa sa mechine, joalo-joalo, hammoho le likarolo tsa mekhoa ea mechine.Ho phaella moo, ha ho kobeha le matla a torsional a tšoana, boima ba 'mele bo bobebe, kahoo bo boetse bo sebelisoa haholo ha ho etsoa likarolo tsa mechine le mehaho ea boenjiniere.E boetse e sebelisoa hangata joalo ka thepa ea ka tlung le kitchenware, joalo-joalo.

Hlokomela:

1.Free sampling, 100% ka mor'a ho rekisa boleng ba boleng, Tšehetsa mokhoa leha e le ofe oa ho lefa;

2.Litlhaloso tse ling tsohle tsa liphaephe tsa tšepe tse pota-potileng tsa carbon li fumaneha ho ea ka tlhokahalo ea hau (OEM & ODM)!Theko ea fektheri u tla e fumana ho ROYAL GROUP.

Lisebelisoa tsa Lik'hemik'hale tsa Pipe ea Stainless

| Sebopeho sa Lik'hemik'hale % | ||||||||

| Kereiti | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0 .15 | ≤0 .75 | 5. 5-7.5 | ≤0.06 | ≤ 0.03 | 3.5 -5,5 | 16 .0 -18.0 | - |

| 202 | ≤0 .15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - |

| 301 | ≤0 .15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - |

| 302 | ≤0 .15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - |

| 304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0 .03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 - 15.0 | 16 .0 -1 8.0 | 2.0 -3.0 |

| 321 | ≤ 0 .08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 - 13 .0 | 17.0 -1 9.0 | - |

| 630 | ≤ 0 .07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - |

| 631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7,75 | 16.0-18.0 | - |

| 904L | ≤ 2 .0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0 · 28.0 | 19.0-23.0 | 4.0-5.0 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19 -0.22 | 0. 24 -0 .26 | - |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13,5 | - |

| 430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | |

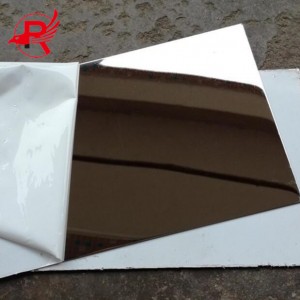

Ka mekhoa e fapaneng ea ts'ebetso ea ho roala ho batang le ho ntlafatsa ka holim'a metsi ka mor'a ho bilika, ho qeta holim'a tšepe e sa hloekangbars e ka ba le mefuta e fapaneng.

Ts'ebetso ea holim'a phala ea tšepe e sa hloekang e na le NO.1, 2B, No. 4, HL, No. 6, No. 8, BA, TR hard, Rerolled bright 2H, polishing bright and other surface finishes, joalo-joalo.

NO.1: No. 1 holim'a metsi e bua ka holim'a metsi a fumanoang ka phekolo ea mocheso le pickling ka mor'a hore ho be le mocheso o chesang oa pipe ea tšepe e sa hloekang.Ke ho tlosa sekala sa black oxide se hlahisoang nakong ea ho chesa le ho phekola mocheso ka pickling kapa mekhoa e tšoanang ea phekolo.Ena ke No. 1 ea tšebetso ea holim'a metsi.Sebaka sa No.1 se bosoeu ba silevera le matt.Haholo-holo e sebelisoa liindastering tse thibelang mocheso le ho bola tse sa hlokeng ho phatsima holimo, joalo ka indasteri ea joala, indasteri ea lik'hemik'hale le lijana tse kholo.

2B: Sebaka sa 2B se fapane le sebaka sa 2D ka hore se boreleli ka rolara e boreleli, kahoo e khanya ho feta sebaka sa 2D.Bokaholimo ba Ra boleng bo lekantsoeng ka sesebelisoa ke 0.1~0.5μm, e leng mofuta o tloaelehileng oa ho sebetsa.Mofuta ona oa tšepe e sa hloekang holim'a metsi ke o fapaneng ka ho fetisisa, o loketseng merero e akaretsang, e sebelisoang haholo lik'hemik'hale, pampiri, peterole, liindasteri tsa bongaka le tse ling, hape e ka sebelisoa e le lerako la lesira la mohaho.

TR Hard Finish: TR tšepe e sa hloekang e boetse e bitsoa tšepe e thata.Likarolo tsa eona tsa tšepe tse emelang ke 304 le 301, li sebelisetsoa lihlahisoa tse hlokang matla le boima bo phahameng, tse kang likoloi tsa terene, mabanta a lipalangoang, liliba le li-gaskets.Molao-motheo ke ho sebelisa litšobotsi tse thata tsa mosebetsi oa austenitic tšepe e sa hloekang ho eketsa matla le ho thatafala ha poleiti ea tšepe ka mekhoa e batang ea ho sebetsa e kang ho roala.Thepa e thata e sebelisa liphesente tse 'maloa ho isa ho mashome a' maloa a liperesente tsa ho thetheha ha bobebe ho nkela sebaka se bataletseng sa bokaholimo ba 2B, 'me ha ho na annealing e etsoang ka mor'a ho bilika.Ka hona, sebaka se thata sa TR sa thepa e thata ke sebaka se phuthoang ka mor'a ho bata.

Rerolled Bright 2H: Kamora ts'ebetso ea ho phutha.phala ea tšepe e sa hloekang e tla sebetsoa ka annealing e khanyang.Pipe e ka pholile ka potlako ka mohala o tsoelang pele oa annealing.Lebelo la ho tsamaea la phala ea tšepe e sa hloekang moleng ke ho pota 60m ~ 80m / min.Kamora mohato ona, pheletso ea bokaholimo e tla ba 2H e nchafalitsoeng e khanyang.

No.4: Bokaholimo ba No. 4 ke sebaka se setle se bentšitsoeng hantle se khanyang ho feta bokaholimo ba No. 3. E boetse e fumanoa ka ho bentša phala ea tšepe e sa batang e pota-potiloeng ka 2 D kapa 2 B e le setsi le ho bentša ka lebanta le hlabang le boholo ba lijo-thollo tsa 150-180 # Sebaka se entsoeng ka mochine.Bokaholimo ba Ra boleng bo lekantsoeng ka sesebelisoa ke 0.2~1.5μm.Sebaka sa NO.4 se sebelisoa haholo lireschorenteng le lisebelisoa tsa kichineng, lisebelisoa tsa bongaka, mekhabiso ea meralo, lijana, joalo-joalo.

HL: HL surface e atisa ho bitsoa hairline finish.Tekanyetso ea Japane ea JIS e bolela hore lebanta la abrasive la 150-240# le sebelisoa ho bentša mothapo o sa khaotseng oa moriri o kang oa makhopho o fumanoeng.Ho maemo a China a GB3280, melaoana ha e hlaka.Qetello ea bokaholimo ba HL e sebelisoa haholo bakeng sa mokhabiso oa moaho joalo ka lilifti, li-escalator le lifensetere.

CheSebaka sena se na le khanya e ntle ea tšepe le ts'ebetso e bonolo.Pontšo e fokola 'me ha e bontše setšoantšo.Ka lebaka la thepa ena e ntle, e loketse haholo ho etsa marako a likharetene tsa mohaho le mekhabiso ea ho haha mehaho, hape e sebelisoa haholo e le lisebelisoa tsa kichineng.

BA: BA ke bokaholimo bo fumanoang ke kalafo e khanyang ea mocheso ka mor'a hore ho pholile ho bata.Kalafo e khanyang ea mocheso e annealing tlas'a sepakapaka se sireletsang se tiisang hore bokaholimo ha bo na oxidized ho boloka khanya ea bokaholimo bo batang, ebe o sebelisa rolo e nepahetseng e phahameng ea boreleli bakeng sa boemo ba khanya ho ntlafatsa khanya ea bokaholimo.Sebaka sena se haufi le ho qeta seipone, 'me bokaholimo ba Ra boleng bo lekantsoeng ke sesebelisoa ke 0.05-0.1μm.BA surface e na le mefuta e mengata ea tšebeliso 'me e ka sebelisoa e le lisebelisoa tsa kichineng, lisebelisoa tsa ntlo, lisebelisoa tsa bongaka, likarolo tsa likoloi le mekhabiso.

No.8: No.8 ke seipone se phethiloeng holim'a seipone se nang le ponahalo e phahameng ka ho fetisisa ntle le lithollo tse senyang.Indasteri ea ts'ebetso e tebileng ea tšepe e se nang tšepe e boetse e bitsa lipoleiti tsa 8K.Ka kakaretso, lisebelisoa tsa BA li sebelisoa e le lisebelisoa tse tala tsa seipone ho qeta feela ka ho sila le ho bentša.Kamora ho qeta seipone, bokaholimo ke botaki, ka hona bo sebelisoa haholo ho aha mokhabiso oa monyako le mokhabiso oa kahare.

Ts'ebetso ea mantlha ea tlhahiso: tšepe e chitja → ho hlahloba hape → ho ebola → ho koala → ho koala → ho futhumatsa → ho penta → ho phunya → hlooho e bataletseng → ho hlahloba le ho sila → ho roala ho batang (setšoantšo se batang) → ho tlosa mocheso → phekolo ea mocheso → ho otlolla → ho khaola liphaephe (tse tsitsitseng-ho -bolelele) )→ pickling/passivation→ tlhahlobo ea sehlahisoa se felileng (eddy current, ultrasonic, khatello ea metsi)→ho paka le ho boloka.

1. Ho itšeha ka tšepe e pota-potileng: Ka mor'a ho amohela tšepe e pota-potileng ho tloha sebakeng sa polokelo ea thepa e tala, bala bolelele ba ho itšeha ba tšepe e chitja ho ea ka litlhoko tsa ts'ebetso, 'me u hule mola holim'a tšepe e chitja.Litšepe li kenngoa ho ea ka limaraka tsa tšepe, linomoro tsa mocheso, linomoro tsa lihlahisoa tsa lihlahisoa le litlhaloso, 'me lipheletsong li khetholloa ka lipente tsa mebala e fapaneng.

2. Centering: Ha u beha setsi sa mochine oa ho phunya letsoho la sefapano, qala ka ho fumana ntlha e bohareng karolong ea tšepe e chitja, phunya lesoba la mohlala, ebe u e lokisa ka ho toba holim'a tafole ea mochine oa ho phunya bakeng sa centering.Li-bars tse pota-potileng ka mor'a hore li behoe li behiloe ho latela boemo ba tšepe, palo ea mocheso, litlhaloso le palo ea batch ea tlhahiso.

3. Peeling: peeling e etsoa ka mor'a ho feta tlhahlobo ea lisebelisoa tse kenang.Ho ebola ho kenyelletsa ho ebola ha lathe le ho seha ha sefefo.Ho phunya lathe ho etsoa holim'a lathe ka mokhoa oa ho sebetsa oa clamp e le 'ngoe le top e le' ngoe, 'me ho khaola ha sefefo ke ho fanyeha tšepe e chitja holim'a sesebelisoa sa mochine.Etsa whirling.

4. Tlhahlobo ea holim'a metsi: Tlhahlobo ea boleng ba tšepe e pota-potileng e entsoeng ka peeled e etsoa, 'me mefokolo e teng ea holim'a metsi e tšoauoa,' me basebetsi ba sila ba tla ba sila ho fihlela ba tšoaneleha.Libaka tse pota-potileng tse fetisitseng tlhahlobo li bokelloa ka thoko ho ea ka sehlopha sa tšepe, palo ea mocheso, tlhaloso le palo ea batch ea tlhahiso.

5. Ho futhumatsa tšepe e chitja: Thepa ea ho futhumatsa tšepe e chitja e kenyelletsa sebōpi sa leifo se chesitsoeng ka khase le sebōpi sa mofuta oa lebokose le chesitsoeng ka khase.Sebōpi sa pelo e chesitsoeng ka khase se sebelisetsoa ho futhumatsa ka lihlopha tse kholo, 'me sebōpi sa mofuta oa mabokose a khase se sebelisetsoa ho futhumatsa ka lihlopha tse nyenyane.Ha u kena ka sebōping, mekoallo e pota-potileng ea lihlopha tse fapaneng tsa tšepe, linomoro tsa mocheso le litlhaloso li aroloa ke filimi ea khale ea ka ntle.Ha mekoallo e chitja e futhumatsoa, li-turners li sebelisa lisebelisoa tse khethehileng ho fetola mekoallo ho netefatsa hore litšepe tse chitja li futhumatsoa ka ho lekana.

6. Ho phunya ho phunyang ho chesang: sebelisa yuniti ea ho phunya le compressor ea moea.Ho ea ka litlhaloso tsa tšepe e pota-potileng e pota-potiloeng, ho khethoa lipoleiti tse tsamaisanang tsa tataiso le li-plug tsa molybdenum, 'me tšepe e pota-potileng e futhumetseng e phunyeletsoa ka perforator,' me liphaephe tsa litšila tse phunyeletsoeng li kenngoa ka letamo bakeng sa ho pholile ka ho feletseng.

7. Ho hlahloba le ho sila: Hlahloba hore na bokaholimo le bokantle ba phala ea litšila bo boreleli ebile bo boreleli, 'me ha hoa lokela ho ba le letlalo la lipalesa, mapetsong, li-interlayers, likoti tse tebileng, likhoele tse tebileng, tšepe ea tora, fritters, Baotou le lihlooho tsa sekele. .Litšitiso tse holim'a phala ea litšila li ka felisoa ka mokhoa oa ho sila sebakeng seo.Liphaephe tsa litšila tse fetileng tlhahlobo kapa tse fetileng tlhahlobo ka mor'a ho lokisoa le ho sila ka mefokolo e nyane li tla kopanngoa ke li-bundlers tsa workshop ho ea ka litlhoko, 'me li phuthetsoe ho ea ka sehlopha sa tšepe, nomoro ea sebōpi, litlhaloso le palo ea lihlahisoa tsa tlhahiso. ea phala ea litšila.

8. Ho otlolla: Liphaephe tsa litšila tse kenang setsing sa mosebetsi oa ho phunyeletsa li tletse ka dingata.Sebopeho sa phala ea litšila e kenang e kobehile 'me e hloka ho otloloha.Thepa ea ho otlolla ke mochini o otlolohileng o otlolohileng, mochini o otlolohileng o otlolohileng le mochini o otlolohileng oa hydraulic (o sebelisetsoang ho otlolla pele ha phala ea tšepe e na le sekhahla se seholo).E le ho thibela phala ea tšepe hore e se ke ea qhoma nakong ea ho otloloha, letsoho la nylon le sebelisoa ho fokotsa phala ea tšepe.

9. Ho khaola liphaephe: Ho ea ka moralo oa tlhahiso, phala ea litšila e otlolohileng e hloka ho khaola hlooho le mohatla, 'me thepa e sebelisoang ke mochine oa ho senya lebili.

10. Pickling: Pipe ea tšepe e otlolohileng e hloka ho khethoa ho tlosa sekala sa oxide le litšila holim'a phala ea litšila.Peipi ea tšepe e tšeloa ka setsing sa ho kha, 'me peipi ea tšepe e phahamisoa butle-butle ka tanka ea ho kha bakeng sa ho kha ka ho khanna.

11. Ho sila, tlhahlobo ea endoscopy le ho belisoa ha ka hare: liphaephe tsa tšepe tse tšoanelehang bakeng sa pickling li kena ka ntle holim'a ts'ebetso ea ho sila, lipeipi tsa tšepe tse bentšitsoeng li tlas'a tlhahlobo ea endoscopic, 'me lihlahisoa kapa lits'ebetso tse sa tšoanelehang tse nang le litlhoko tse khethehileng li hloka ho sebetsanoa ka hare. ka.

12. Mokhoa o batang oa ho roala / mokhoa o batang oa ho taka

Cold rolling: Peipi ea tšepe e phuthoa ke meqolo ea leloala le batang, 'me boholo le bolelele ba phala ea tšepe li fetoloa ke ho fetoha ha serame ho tsoelang pele.

Setšoantšo se batang: Pipe ea tšepe e chesoa 'me e fokotsoa leboteng ka mochine o batang oa ho taka ntle le ho futhumatsa ho fetola boholo le bolelele ba phala ea tšepe.Pipe ea tšepe e huloang ka serame e na le ho nepahala ho phahameng le ho qeta hantle holimo.Bothata ke hore khatello e setseng e kholo, 'me hangata lipeipi tse huloang ka serame tse kholo li sebelisoa hangata,' me sehlahisoa se phethiloeng se etsa lebelo le liehang.Mokhoa o ikhethileng oa ho taka o batang o kenyelletsa:

① Hlooho ea ho cheselletsa hlooho: Pele ho penta e batang, ntlha e le 'ngoe ea phala ea tšepe e lokela ho tsamaisoa (peipi e nyane ea tšepe) kapa hlooho ea welding (peipi e kholo ea tšepe) ho itokisetsa mokhoa oa ho taka, le phala e nyane e khethehileng ea tšepe. e hloka ho futhumatsoa ebe o ea.

② Lubrication le ho baka: Pele ho penta e batang ea phala ea tšepe ka mor'a hlooho (hlooho ea welding), lesoba le ka hare le bokantle ba phala ea tšepe li tla tlotsoa, 'me phala ea tšepe e tlatsitsoeng ka lubricant e tla omisoa pele ho setšoantšo se batang.

③ Setšoantšo se batang: Pipe ea tšepe ka mor'a hore lubricant e omisoe e kene ka mokhoa o batang oa ho taka, 'me thepa e sebelisetsoang ho taka e batang ke mochine oa ho taka o batang oa ketane le mochine oa ho taka oa hydraulic.

13. Ho fokotsa mocheso: Sepheo sa ho fokotsa mafura ke ho tlosa oli e pota-potileng e khomaretsoeng leboteng le ka hare le bokantle ba ka ntle ba phala ea tšepe ka mor'a ho phunya ka ho hlatsoa, e le ho qoba ho silafatsa holim'a tšepe nakong ea annealing le ho thibela ho eketseha ha carbon.

14. Kalafo ea mocheso: Phekolo ea mocheso e tsosolosa sebōpeho sa thepa ka ho recrystallization le ho fokotsa ho hanyetsa deformation ea tšepe.Thepa ea ho futhumatsa mocheso ke tharollo ea khase ea tlhaho sebōpi sa phekolo ea mocheso.

15. Pickling ea lihlahisoa tse feliloeng: Liphaephe tsa tšepe ka mor'a ho khaola li kenngoa ka ho qeta ho khethoa ka morero oa ho fokotsa holim'a metsi, e le hore filimi e sireletsang oxide e ka thehoa holim'a liphaephe tsa tšepe le ho ntlafatsa ts'ebetso e babatsehang ea liphaephe tsa tšepe.

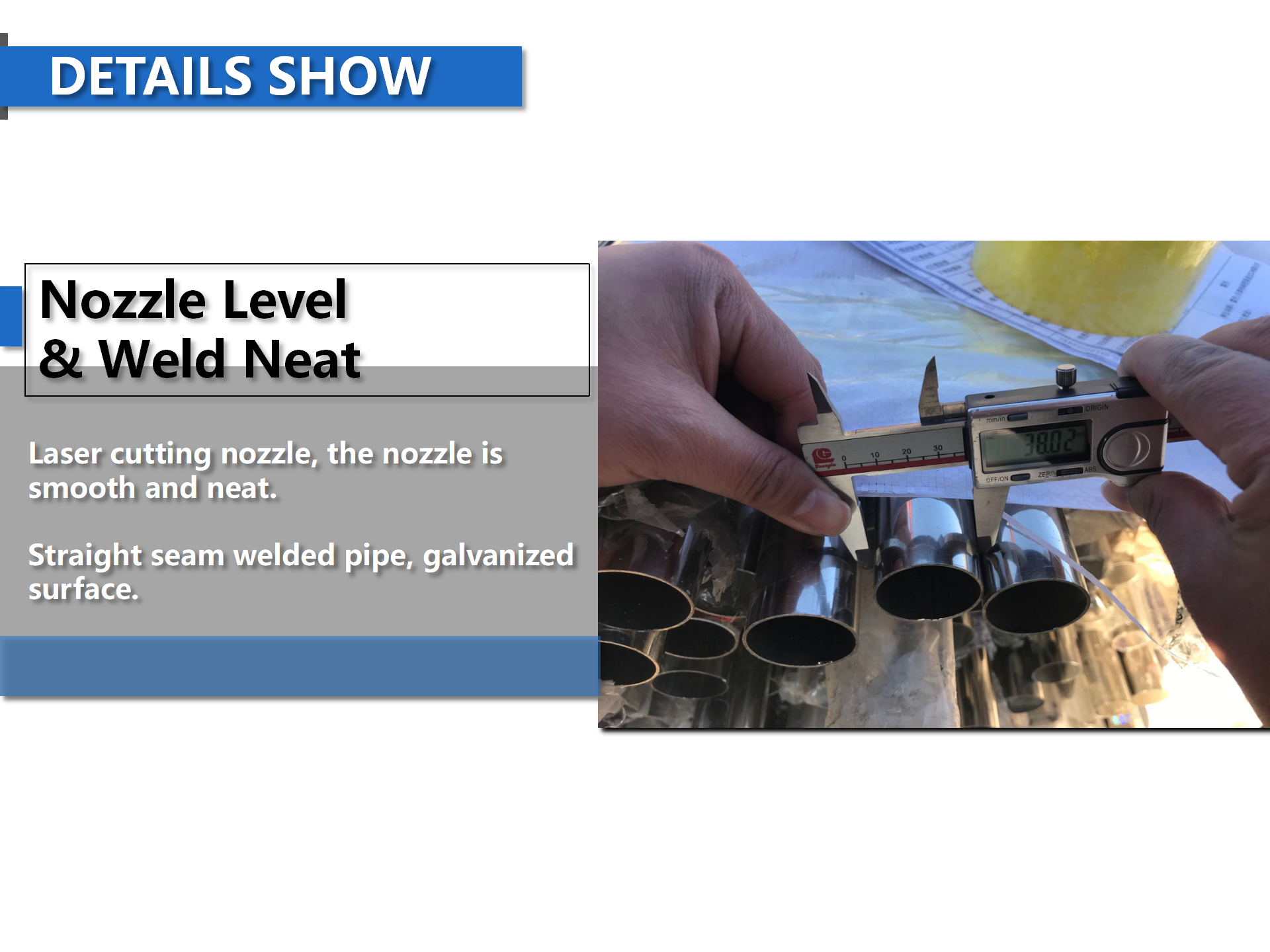

16. Tlhahlobo e phethiloeng ea sehlahisoa: Mokhoa o ka sehloohong oa tlhahlobo le tlhahlobo ea sehlahisoa se felileng ke tlhahlobo ea metara → probe ea eddy → super probe → khatello ea metsi → khatello ea moea.Tlhahlobo ea holim'a metsi ke haholo-holo ho hlahloba ka letsoho hore na ho na le mefokolo holim'a phala ea tšepe, hore na bolelele ba phala ea tšepe le boholo ba lerako le ka ntle li tšoaneleha;ho lemoha eddy haholo-holo ho sebelisa mochine oa eddy oa hona joale oa phoso ho hlahloba hore na ho na le likheo phapeng ea tšepe;super-detection haholo-holo e sebelisa ultrasonic flaw detector ho hlahloba hore na pipe ea tšepe e phunyehile ka hare kapa ka ntle;khatello ea metsi , Khatello ea moea ke ho sebelisa mochine oa hydraulic le mochine oa khatello ea moea ho bona hore na phala ea tšepe e ntša metsi kapa moea, e le ho etsa bonnete ba hore phala ea tšepe e boemong bo botle.

17. Ho paka le ho boloka thepa: Liphaephe tsa tšepe tse fetileng tlhahlobo li kena sebakeng se phethiloeng sa ho paka bakeng sa ho paka.Lisebelisoa tse sebelisetsoang ho paka li kenyelletsa likoti tsa lesoba, mekotla ea polasetiki, lesela la letlalo la noha, mapolanka a mapolanka, mabanta a tšepe a sa hloekang, joalo-joalo. Karolo e ka ntle ea lipheletsong tse peli tsa pipe ea tšepe e phuthetsoeng e kenngoa ka mapolanka a manyenyane a mapolanka, 'me bokantle ba ka ntle bo tlanngoe ka lesela. mabanta a tšepe ho thibela ho kopana pakeng tsa lipeipi tsa tšepe nakong ea lipalangoang le ho baka ho thulana.Liphaephe tsa tšepe tse kentsoeng li kena sebakeng se phethiloeng sa lihlahisoa.

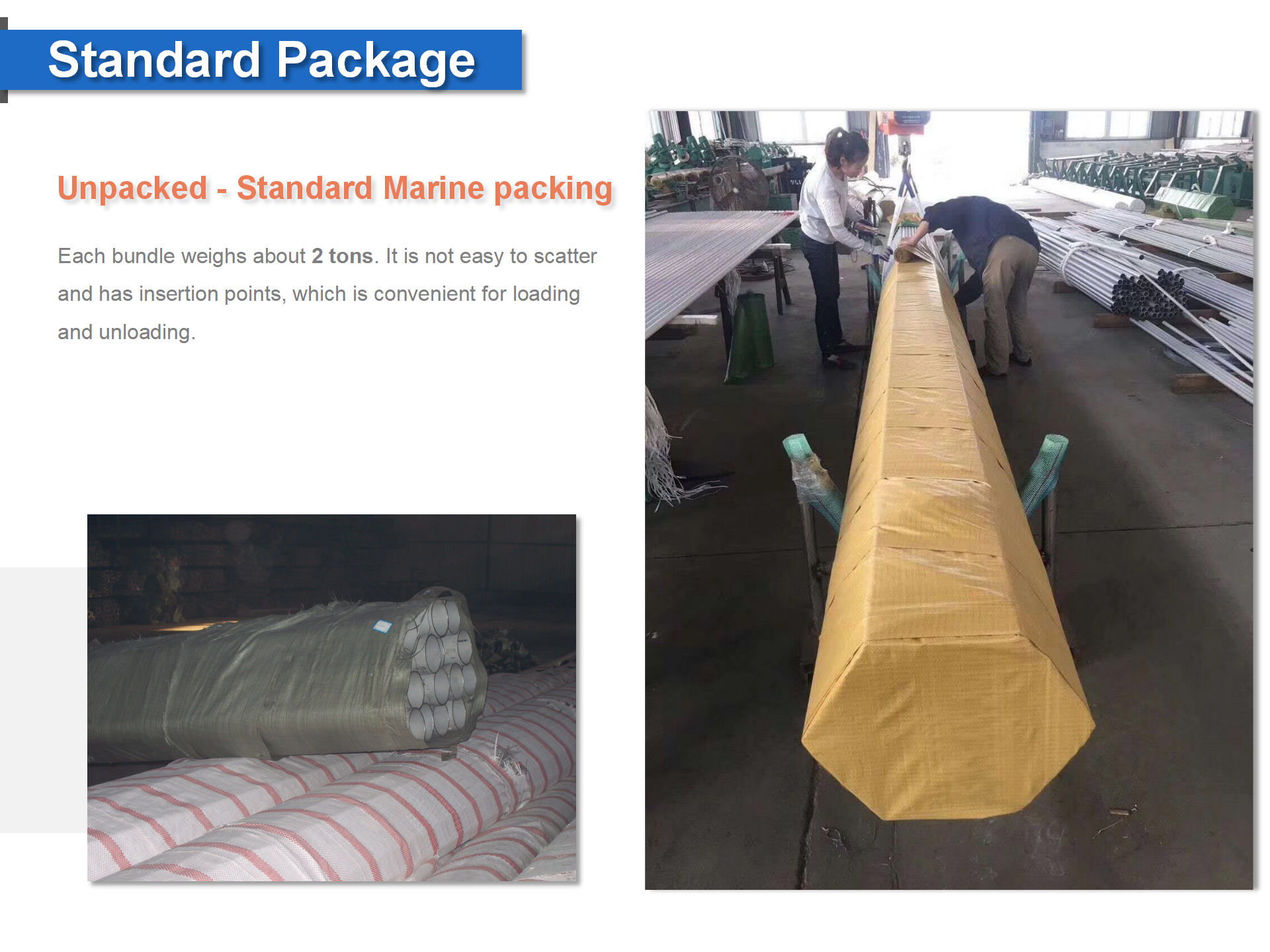

Ho paka ka kakaretso ho hlobotse, ho tlama terata ea tšepe, ho matla haholo.

Haeba u na le litlhoko tse khethehileng, u ka sebelisa liphutheloana tse thibelang mafome, 'me li ntle ho feta.

Lipalangoang:Express (Sample Delivery), Air, Rail, Land, Sea ship (FCL kapa LCL kapa Bulk)

Moreki oa rona

Moreki ea thabisang

Re amohela baemeli ba Machaena ho tsoa ho bareki lefatšeng ka bophara ho etela k'hamphani ea rona, moreki e mong le e mong o tletse ts'epo le ts'epo khoebong ea rona.

P: Na moetsi oa ua?

A: E, re moetsi oa li-tube tsa tšepe tse lulang motseng oa Daqiuzhuang, motseng oa Tianjin, Chaena.

P: Na nka fuoa taelo ea teko feela lithane tse 'maloa?

A: Ehlile.Re ka romella thepa bakeng sa hau ka LCL serivece.(Moroalo o fokolang oa setshelo)

P: Na u na le boemo bo holimo ba tefo?

A: Bakeng sa taelo e kholo, matsatsi a 30-90 L / C a ka amoheleha.

P: Haeba sampole e lokolohile?

A: Mohlala oa mahala, empa moreki o lefella thepa.

P: Na u morekisi oa khauta 'me u etsa tiisetso ea khoebo?

A: Re lilemo tse supileng tse batang mofani oa thepa 'me re amohela tiisetso ea khoebo.